Showing 1–30 of 36 results

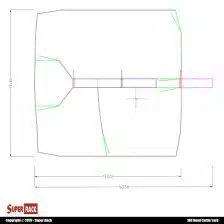

Super Rack is one of the leading suppliers of cattle panel and cattle yard system in Brisbane and Melbourne. Our products are built with superior heavy-duty quality, with all metals being at least 1.6mm thick. All of our cattle panels and gates come with pins and brackets to lock the panels together and are metal capped to keep the rain out. Our products are sturdy and reliable, and there is no fear of the structure collapsing because they are made from the highest quality galvanized steel. Our cattle yard plans are designed to aid in processing and securing livestock, ensuring efficient workflow, and, most importantly, providing a safe working environment.

In the world of agriculture, effective cattle yard design is essential for the safety and productivity of your herd. At Super Rack, we understand the importance of a well-designed cattle panel and cattle yard system. Our commitment to providing top-notch quality at very reasonable prices, combined with our vast stock and customizsation options, makes us the go-to choice for farmers and ranchers looking to enhance their livestock management.

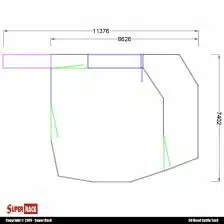

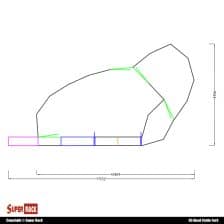

4000 to 4182

4186 to 4207

4300 to 4305

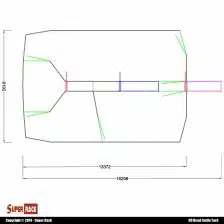

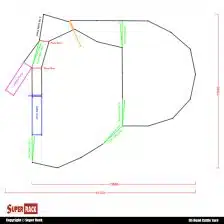

3000 To 3096

3098 To 3112

3114 To 3138

3140 To 3157

3161 To 3198

3200 To 3207

Let's connect