Super Rack is a leading cantilever racking supplier in Brisbane And Melbourne, and we sell the most popular timber storage rack.

We offer brand new warehouse racking at the best price, and we strive to find the best storage solution for each customer.

Our cantilever racking is produced with exceptional quality, as we believe that safety and durability are the most important for storage systems.

They are the most popular timber storage racking and are ideal for timber storage, lumber yards, woodworking shops, steel storage, and plumbing supply warehouses. (source).

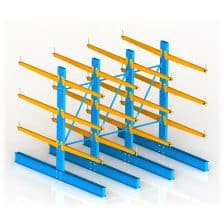

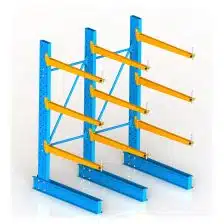

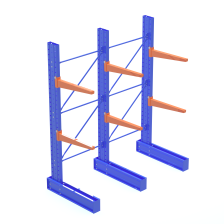

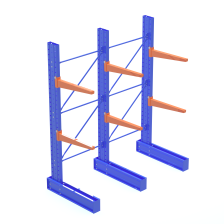

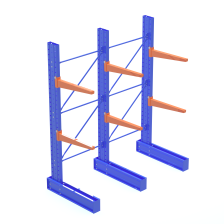

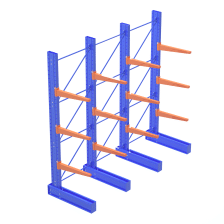

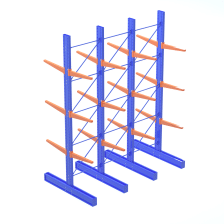

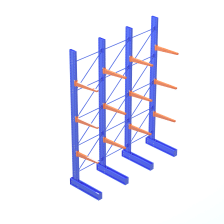

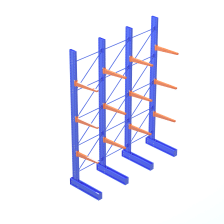

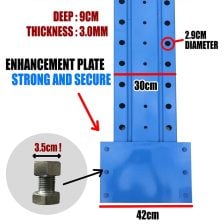

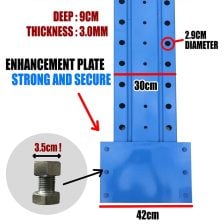

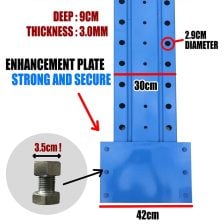

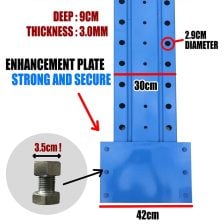

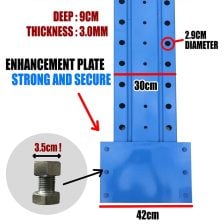

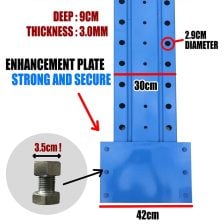

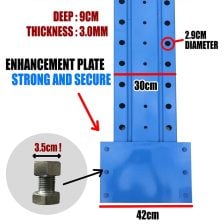

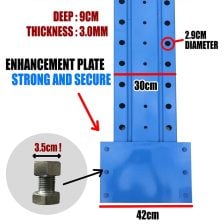

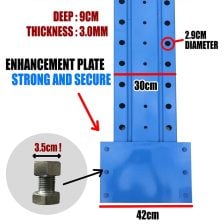

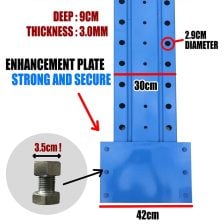

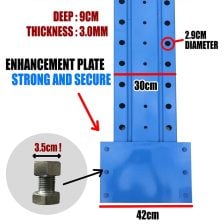

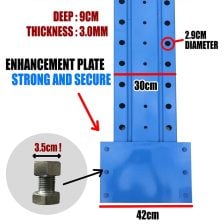

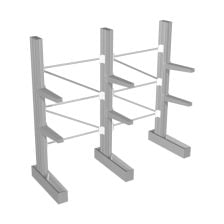

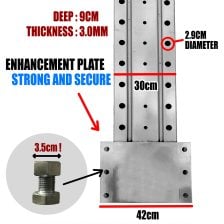

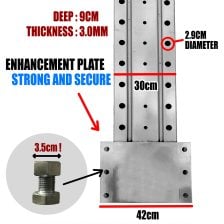

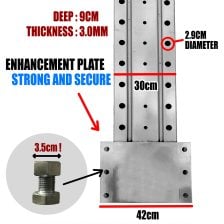

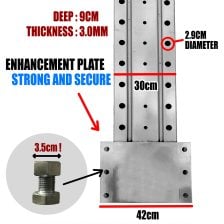

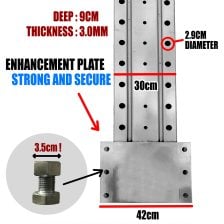

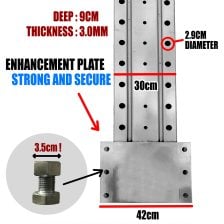

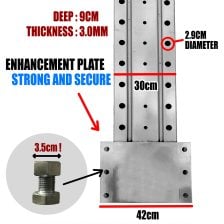

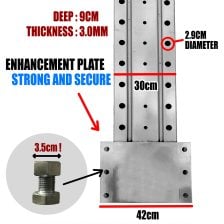

So what exactly makes our cantilever racking special? Firstly, our upright is consist of enhancement plate for strong support. Secondly, the base is bolted directly to the enhancement plate of our upright, for extra support and safety. Lastly, the arm can be adjusted at different angles to suit different needs.

To increase your productivity and/or profitability, contact us now – speak to any of our many industry professionals who will guide you to the very best storage solutions for your needs.

Currently, we have customer service centres and warehouses in Brisbane and Melbourne.

In Super Rack, we design and supply different type of cantilever racking storage systems to fit your needs. If you have a plan, our professional team can work with you to satisfy all your requirements. Otherwise, you can show us your floor plan, and we would do the rest for you.

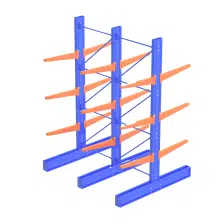

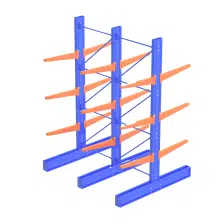

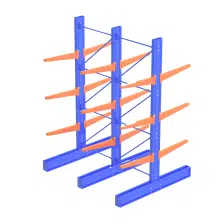

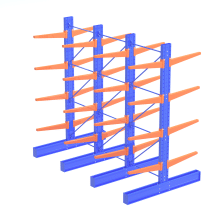

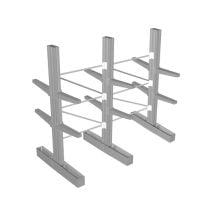

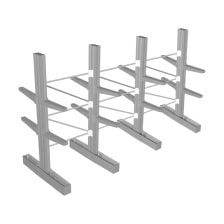

Cantilever Racking is a specific type of warehouse storage system. It is a combination of the vertical column, base, arms, and bracing. In addition, the bracing is used for joining two or more cantilever bays together.

They are usually using for storing bulky oversized items such as timber, plasterboard, steel, pipe, tube, and steel. Moreover, they are the most popular timber storage rack in Australia.

We offer light-duty and heavy-duty models to fulfil different requirements. For heavy-duty models, we offer both Powder-Coated and Hot-Dipped-Galvanised cantilever racking systems for indoor and outdoor use.

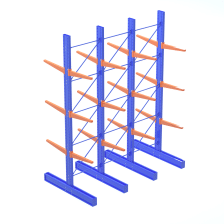

This type of racking advantages for storing various types of bulky over-sized long loads such as timber, plasterboard, steel trusses & piping and PVC carpet. It was designed to hold very heavy loadings and for easy access with forklifts. To sum up, it is a very practical storage system for warehousing.

When designing your Cantilever Racking System, please pay attention to the height of your building and the range of your forklift, they are the main factors that you should consider when choosing the right upright size.

On the other hand, to choose the right Arm size, you should make sure your products must never exist the length of the arm, for instance, if your products are 1000mm deep, then you need 1200mm length arm at minimum, also please keep in mind that the arms are not overloaded.

Brisbane Office

34 Kelliher Road, Darra, QLD 4076

P: 07 3375 9688

Melbourne Office

1B/20 Prestige Place, Truganina, VIC 3029

P: 03 9315 2753

Copyright © Since 1992. Super Rack | Terms & Conditions | Privacy Policy | Return Policy