Let’s get straight to it. Small business inventory management is the process of ordering, storing, using, and selling your business’s stock. This covers everything from raw materials to finished products, including how you warehouse and handle them. Think of it as the engine that drives your cash flow and keeps customers happy.

For any Aussie small business, mastering your stock is a must. It doesn’t matter if you’re a plumber in Perth with spare parts in the ute or a booming online shop in Melbourne—how you handle your goods directly hits your bottom line. This is much more than just counting boxes on a shelf.

To get started, it helps to understand what Inventory Management is really about. At its heart, it’s about having the right stock, in the right place, at the right time, and at the right cost. When you get those four things balanced, your business just works better.

Getting it wrong, on the other hand, can be a massive drain. For a lot of small businesses in Australia, inventory is a huge chunk of their assets. Stock can make up 20-30% of a small business’s total assets, and mismanaging it can lead to serious financial losses.

Poor stock control creates a domino effect. It isn’t about one or two little mistakes; it’s a chain reaction of problems that can seriously hurt your business over time.

Here are a few of the classic stuff-ups:

“Effective inventory management is the backbone of a healthy retail or trade business. It transforms stock from a simple asset into a dynamic tool for growth, ensuring you can meet customer demand without wasting capital.”

Ultimately, smart small business inventory management is all about efficiency. It lets a Brisbane warehouse manager find goods in seconds using heavy-duty pallet racking. It helps a farmer setting up new cattle yards know they’ve got enough fencing panels on hand for the job. It turns your stock from a headache into a real competitive advantage.

Finding the best way to handle your small business inventory management isn’t about picking the most complicated system; it’s about choosing one that actually makes sense for what you do and sell.

Let’s be clear: there’s no single magic solution that works for every Aussie business. The right method for a café juggling fresh produce will be totally different from a workshop that stocks nuts and bolts.

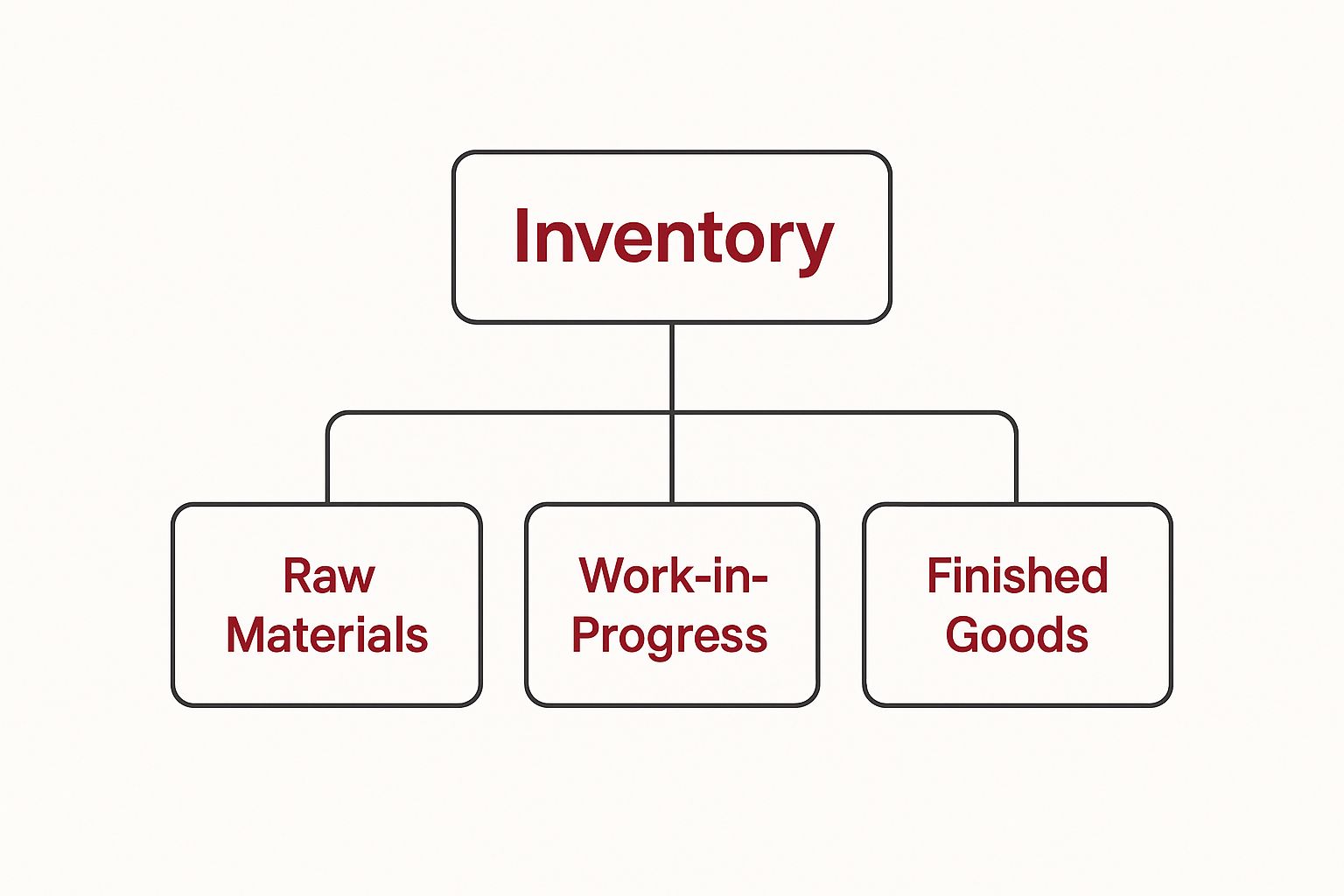

To get started, it helps to see how inventory is typically grouped. Understanding these categories is the first step in applying the right control method to the right type of stock. This simple diagram shows the three main stages your products go through.

As you can see, inventory starts as raw materials, becomes a work-in-progress, and finishes as the final product ready to go out the door.

Now, let’s dive into two of the most practical and effective inventory control methods for small businesses. These strategies will help you bring some much-needed order to your stockroom and make smarter decisions about your products.

The First-In, First-Out (FIFO) method is exactly what it sounds like: the first items that land in your stockroom are the first ones you sell. It’s a simple but powerful principle, especially if you deal with products that have a shelf life or can become outdated.

Think about running an auto parts store in Brisbane. You get a fresh shipment of oil filters. With FIFO, you’d simply place the new stock behind the older filters on your garage shelving, making sure customers always grab the oldest stock first. This cuts down on waste and keeps product quality high.

FIFO is a must for:

This method also keeps your accounting accurate by matching the cost of your oldest inventory against your current revenue.

Let’s face it, not all stock is created equal. ABC analysis is a clever way to prioritise your inventory by sorting it into three categories based on its value to your business. It’s built on the Pareto Principle, which suggests that roughly 80% of your revenue flows from just 20% of your products.

By sorting your items this way, you can focus your time and energy where they’ll have the biggest impact. It stops you from spending as much effort tracking a box of cheap washers as you do on your best-selling items.

Here’s how the breakdown usually works:

A farm supplier in regional Queensland might use ABC analysis to classify their stock. Heavy-duty fencing panels and cattle yards would be ‘A’ items, requiring careful management. Mid-range gear like water troughs could be ‘B’ items, while basic bolts and clips are clear ‘C’ items.

This approach ensures you never run out of your most profitable products while keeping the admin for less critical items simple. Choosing the right method is a huge step towards a small business inventory management system that saves you money and stress.

Even the slickest inventory software will fall flat if your stockroom is a chaotic mess. Great small business inventory management starts with a smart, organised physical space. Getting this right slashes picking times, reduces errors, and makes your entire operation run smoother.

Think of your storage area like a well-planned city grid. When everything has a logical place, work flows smoothly, and finding what you need is quick and easy. A disorganised stockroom, on the other hand, is a recipe for frustration and wasted time.

A logical layout is the foundation of any efficient workspace. The goal is to minimise the number of steps your team takes to find and pick an order. A well-designed flow can dramatically cut down on labour costs and fulfilment times.

For example, a common layout places your most popular products (your ‘A’ items) closest to the packing stations. This simple change means your team spends most of their time in a small, efficient zone instead of walking to the back of the warehouse for every other order.

Here are a few practical tips for designing your layout:

A well-planned layout isn’t just about speed; it’s also about safety. Keeping walkways clear and ensuring there is enough space for staff and equipment to move freely reduces the risk of accidents.

Once you have a layout, the next step is choosing the right physical storage. The shelving and racking you use are the backbone of your inventory system. The right solution protects your products, maximises your space, and makes stock easily accessible.

The needs of a small workshop are vastly different from a large warehouse. For instance, a mechanic in Adelaide managing small parts would benefit from sturdy garage shelving. It allows for easy organisation of smaller items, keeping everything visible and within reach.

On the other hand, a distribution centre in Sydney handling bulk goods requires heavy-duty pallet racking. This system uses vertical space efficiently, allowing for high-density storage while ensuring pallets are safely accessible with a forklift. Super Rack offers nationwide service, ensuring businesses from Brisbane to Perth can get expert advice and the right setup.

“Investing in the right storage infrastructure isn’t an expense—it’s a direct investment in your operational efficiency. The right racking system can double your storage capacity and cut order picking times by more than half.”

The key is to match the storage solution to the product. For example, cantilever racking is perfect for long, awkward items like timber or steel pipes, while heavy-duty shelving is ideal for organising boxed goods.

When setting up, it can be tempting to cut costs by buying used racking. However, this often turns out to be a false economy. The risks that come with used equipment can lead to far greater costs down the line from accidents, product damage, or compliance failures.

Investing in new, high-quality racking from a trusted supplier like Super Rack offers peace of mind and long-term value. New racking is engineered to meet current Australian safety standards, ensuring your workplace is compliant and your team is safe.

Here’s why buying new is a smarter choice:

Ultimately, organising your physical stock is about creating a safe and productive environment. With a smart layout and the right heavy-duty storage, your small business inventory management becomes simpler and more profitable. Contact Super Rack for a free quote today.

Ready to ditch the old pen-and-paper method? Choosing the right tools is a massive step forward for any small business trying to nail its inventory management. This isn’t about splashing out on a complex system. It’s about finding smart tech that automates the boring stuff and gives you the data you need to make better decisions.

Most businesses start small and let their tech grow with them. For many, that first step is a simple spreadsheet. But as your business grows, you’ll quickly hit the limits of manual entry, and that’s when it’s time to look at dedicated solutions.

If you’re just getting off the ground, a well-organised spreadsheet can be a fantastic first tool. It’s cheap (often free!), easy to use, and flexible enough to track basic stock levels, costs, and sales. You can quickly set up columns for SKUs, product descriptions, quantities on hand, and supplier details.

The downside? Spreadsheets are prone to human error. One little typo can throw your entire stock count into disarray, leading to incorrect orders. They also don’t update in real-time, making them a risky choice if you’re juggling multiple sales channels.

When your spreadsheet starts to feel like a liability, it’s time for an upgrade. Dedicated inventory management software is a real game-changer for a growing business. These platforms are built specifically to automate the heavy lifting of stock control.

Think about a small retailer in Perth. Integrating their point-of-sale (POS) system with inventory software is a must. Every time an item is sold, the software automatically updates the stock count. This gives them a live, accurate picture of what’s on the shelves at any given moment—no guesswork required.

Good software does far more than just count stock. Look for key features like:

Getting this right is especially critical for compliance. To stay on the right side of the tax office, your physical counts need to match your records, a task made infinitely easier when your inventory system is linked to your sales software. You can get more insights on managing stock for Aussie businesses at traceconsultants.com.au.

To really boost your accuracy, bringing in barcode scanners is the next logical step. Barcodes take manual data entry—and all the errors that come with it—out of the equation. Scanning items as they arrive and as they’re sold ensures your data is 99% accurate or better.

This tech also makes jobs like stocktakes unbelievably fast. Instead of your team manually counting every single item, they can just scan their way through the warehouse. For a business with thousands of SKUs on their garage shelving, this is a lifesaver that frees up countless hours.

For those wanting to take it a step further, there’s Radio-Frequency Identification (RFID). RFID tags transmit data wirelessly, letting you scan multiple items at once without even needing a direct line of sight. While it’s a bigger investment, it offers unmatched speed for larger operations, like a busy Brisbane warehouse tracking high-value goods on its pallet racking.

| Tool | Best For | Pros | Cons |

|---|---|---|---|

| Spreadsheets (Excel, Google Sheets) | New businesses, very small inventories, tight budgets. | Free or low-cost, highly flexible, easy to learn. | Prone to human error, no real-time updates, not scalable. |

| Basic Inventory Apps (e.g., Sortly) | Small retailers, service businesses with equipment. | Mobile-friendly, barcode scanning, visual inventory. | Limited integrations, may lack advanced reporting. |

| Integrated eCommerce Platforms (e.g., Shopify Inventory) | Businesses selling primarily online on one platform. | Seamlessly syncs with sales, easy to manage. | Can be limited if you sell across many channels. |

| Dedicated Inventory Software (e.g., Cin7, Unleashed) | Growing businesses, multi-channel sellers, wholesalers. | Powerful automation, deep reporting, robust integrations. | Higher cost, can have a steeper learning curve. |

Ultimately, choosing the right technology is about matching the tool to your business needs and budget. A smart investment here will pay for itself many times over by improving your cash flow, cutting down on waste, and keeping your customers happy.

Having the right tools and a well-organised space is a great start, but solid small business inventory management really boils down to consistent, smart habits. Think of these practices as your playbook for running a tighter, more profitable operation. They’re the day-to-day actions that stop costly mistakes before they happen.

When you put these proven practices into action, you’ll maintain accurate records, avoid frustrating stockouts, and free up cash that would otherwise be stuck on your shelves. It’s all about being proactive, not reactive.

A stocktake is simply a physical count of every single item you have. It’s the only way to know for sure that the numbers in your software match what’s actually in the storeroom. Discrepancies are more common than you’d think—caused by theft, damage, or simple mistakes—and they can throw your entire system out of whack.

So, how often should you do it? That really depends on your business.

No matter which method you land on, consistency is the key. Accurate stocktakes are the bedrock of reliable inventory data.

A reorder point is the minimum stock level an item can hit before you need to order more. Getting this right is a balancing act. Set it too high, and you’ll have cash tied up in excess stock. Set it too low, and you risk a stockout, which means lost sales and unhappy customers.

To calculate a smart reorder point, you need to know two key figures:

For example, a rural supply business knows it takes two weeks to get a delivery of cattle yard fencing. If they sell about 10 panels a week, their lead time demand is 20 panels. They add a safety stock of 5 panels just in case, making their reorder point 25. As soon as their stock hits 25 panels, it’s time to call the supplier.

Forecasting is about looking at past sales data to make an educated guess about what your customers will want in the future. This is what helps a hardware store stock up on supplies before a long weekend, ensuring they have what customers need, right when they need it.

Being able to predict your needs means you can be more efficient, reduce carrying costs, and make your business far more agile.

Your suppliers are more than just vendors—they’re partners in your success. A good relationship can lead to better pricing, more reliable delivery times, and a bit of flexibility when you’re in a tight spot. Keep the lines of communication open, and always pay your bills on time. A reliable supplier who can rush an order to you is worth their weight in gold.

To really pull all these practices together, it helps to follow a structured approach. This step-by-step guide on creating an inventory system is a fantastic resource for building a system from the ground up. Combining a solid system with organised storage, like using stackable stillage cages for loose items, creates a powerful and efficient workflow.

Any good small business inventory management system needs a solid physical foundation. Think about it—the most advanced software in the world can’t help you if your warehouse is a mess. That’s why getting your storage right from the start is so critical, and where a partner like Super Rack comes in.

A well-organised space is the first step towards real efficiency. When everything has a proper home, your team can find, pick, and pack orders faster. This simple change cuts down on labour costs and speeds up dispatch times. It’s all about creating a logical, safe environment that supports your operation.

Choosing the right storage solution isn’t just an expense; it’s an investment in your business’s productivity and safety. At Super Rack, we focus on heavy-duty quality you can rely on, ensuring both your stock and your staff are kept safe. Unlike the gamble you take with used options, our new products are built tough to meet strict Australian standards.

We know that for any small business, budget is a top concern. That’s why we offer competitive pricing without cutting corners on quality. And with fast, nationwide delivery, we can get the right solutions to you, whether you’re in a major city or a regional town.

When building your inventory management system, partnering with a reliable provider of dedicated business storage services can streamline your operations, especially if you need off-site options to manage overflow stock during peak seasons.

Super Rack offers practical, expert advice to help you find the perfect fit for your space. Our range is designed for hardworking Australian businesses:

Let us help you get organised from day one. Contact Super Rack for a free quote today and build the storage foundation your business deserves.

Let’s tackle some of the most common questions we hear from small business owners about inventory management. Here are a few quick, practical answers to get you on the right track.

This is the million-dollar question in small business inventory management. You need enough product to keep customers happy, but not so much that all your cash is tied up in boxes. It’s a classic balancing act.

The key is figuring out your safety stock level. This is a small buffer against unexpected demand or a delay from your supplier. A great place to start is by digging into your sales data. See what your average sales are for a product, then check your supplier’s typical delivery time. Your sweet spot is having enough stock to cover that period, plus a little extra for peace of mind.

Dead stock can be a massive drain on both your finances and your precious warehouse space. Don’t let it sit there gathering dust on your garage shelving. It’s time to take action.

Here are a few proven strategies:

The real trick is spotting these items early. Regular inventory checks will help you identify products that simply aren’t earning their keep.

Honestly, the best stocktake method is the one you’ll actually do consistently. For most small businesses, cycle counting is a fantastic, less painful approach. Instead of a single, chaotic annual count, you just count a small part of your inventory every week or month.

For instance, if your warehouse uses extensive pallet racking, you could simply count one aisle per week. This approach is far less disruptive, helps you catch errors almost immediately, and keeps your data accurate all year round. It turns a dreaded annual task into a simple, manageable routine.

Ready to build the physical foundation for flawless inventory control? The right storage solution makes everything easier. Super Rack offers heavy-duty, reliable racking and shelving designed for hardworking Aussie businesses. Get expert advice and a free quote to organise your space for maximum efficiency. Visit us at https://www.superrack.com.au.

4000 to 4182

4186 to 4207

4300 to 4305

3000 To 3096

3098 To 3112

3114 To 3138

3140 To 3157

3161 To 3198

3200 To 3207

Let's connect