If you're dealing with long, bulky, or just plain awkward items that won't sit nicely on a standard pallet, then cantilever warehouse racking is the specialised storage system you need. Its key feature is a completely open-front design that gets rid of any vertical obstructions, making it the perfect solution for materials like timber, steel pipes, or furniture.

Think of a sturdy tree with strong, adjustable branches. That's the basic idea behind cantilever warehouse racking. You have a central column (the "trunk") that provides all the vertical support, and a series of arms (the "branches") that extend outwards to hold your stock.

This clever structure completely removes the front columns you’d find in traditional pallet racking. The result? Unobstructed horizontal access for forklifts and other handling equipment. This open design is a genuine game-changer for businesses storing non-standard inventory, as it allows direct access to items of any length without having to shuffle other stock around. It means faster loading, less product damage, and much better use of your warehouse's vertical space.

The real-world value of cantilever racking shines in a few common scenarios. Take these for example:

By removing front-facing barriers, cantilever racking fundamentally changes how you approach storing long and cumbersome goods, turning wasted air space into valuable, accessible storage.

At the end of the day, this racking system is about creating efficiency where other systems simply can't. It’s an investment in a smoother workflow, better safety, and getting the most out of every square metre of your facility. For businesses all over Australia, from manufacturing plants to building suppliers, getting the design right is the key to unlocking these benefits. For those interested in the broader economic context of where cantilever racking is utilised, understanding the dynamics of investing in warehouses and industrial spaces is crucial.

Here at Super Rack, we specialise in providing expert advice to design tailored cantilever solutions. We focus on superior quality, competitive pricing, and fast nationwide delivery, ensuring your storage system perfectly matches your operational needs from day one.

It's one thing to say cantilever racking is great for storing awkward items, but what does that actually mean for your business? The real magic is in how its clever, open-front design translates into tangible results: faster handling, smarter use of space, and a safer warehouse for your team.

The first thing you’ll notice is the unobstructed access. With no front columns getting in the way, forklifts and side-loaders can get straight to the stock without having to weave around vertical posts. This simple change makes a huge difference, slashing the time and effort it takes to load and unload.

Think about a steel fabricator. By switching to cantilever, they could cut handling time by as much as 30% because operators can now lift entire bundles of steel beams in a single, clean movement. Less shuffling around also means a lower chance of bumping into the racking, which protects your product and keeps your crew safer.

Cantilever racking is a champion at squeezing the most out of your warehouse's vertical space, especially for non-palletised goods. It lets you go higher than you could with floor stacking, effectively boosting your storage capacity without needing to find a bigger building. For any business feeling the squeeze, that's a massive win against the high cost of relocation.

A furniture warehouse, for instance, could see its storage capacity jump by 40% just by moving from messy floor stacks to a well-designed cantilever system. Not only does this free up priceless floor space for other tasks, but it also makes managing your inventory far more accurate.

The adjustable arms add another layer of value. As your product line evolves, you can easily shift the arms up or down the columns to fit different-sized items. This built-in adaptability means your racking system stays useful for years, protecting your initial investment. While standard pallets have their place, nothing beats the versatility of cantilever for bulky goods. If you deal with a mix of inventory, our guide to pallet warehouse racking can help you figure out the best combination for a truly efficient setup.

By converting unused vertical height into organised, accessible storage, cantilever racking allows businesses to store more inventory in the same footprint, leading to better stock control and improved turnover.

This isn't just theory; it's a proven principle in Australian logistics. We've seen large-scale projects create thousands of new storage locations by pairing cantilever systems with narrow-aisle forklifts, showcasing just how much space you can reclaim. For example, one Melbourne warehouse uses Australian-made cantilever racks to efficiently manage diverse bulky items within its 5,000 m² space, proving the system’s effectiveness at scale. Read more about how Bowen Storage has implemented these systems in Australia.

At the end of the day, all these practical advantages add up to real improvements for your bottom line. A manufacturing plant using cantilever for raw materials will see better inventory turnover simply because stock is visible, easy to reach, and simple to manage. This leads directly to more accurate stocktakes, less waste, and a leaner supply chain.

When you choose a high-quality system from Super Rack, you're getting more than just steel. You're getting our team's expert advice, competitive pricing, and nationwide service, ensuring your cantilever warehouse racking delivers exactly what you need: faster operations, better space usage, and a safer workplace.

Getting to grips with the parts that make up a cantilever warehouse racking system is like studying a sturdy skeleton. Each piece plays a vital role, and knowing what they do helps you compare quotes, spot quality fabrication, and feel confident that your choice will stand the test of time.

When you break it down, you’ll see this isn’t just a bunch of steel—it’s a purpose-built framework designed for reliable strength and stability.

The base anchors the entire rack to the floor and keeps the structure from tipping, no matter how heavily it’s loaded. It bolts straight to your concrete slab and usually matches the length of the arms to keep the centre of gravity in check.

You’ll find two main styles:

Choosing between them depends on your floor plan and traffic flow. At Super Rack, we use heavy-gauge steel for every base, so you know you’re starting with a rock-solid platform.

Think of the upright column as the backbone of your rack. These tall steel beams have a series of punched holes, letting you slot in cantilever arms at different heights.

Key points:

A taller, stronger column means you can exploit every metre of overhead room and stash heavier items without fear of flex or failure.

The arms extend horizontally from the upright columns and directly support your stock. Whether you’re storing timber sheets or lengths of pipe, these are the components doing the heavy lifting.

Styles include:

Match arm length and capacity to your inventory. For a full list of size and load options, check out our full range of heavy-duty cantilever racking sets.

Bracing ties all the uprights together, preventing sway and twist under heavy loads.

The bracing is what turns individual towers into a single, unified storage system. Without proper bracing, the entire structure would lack the lateral stability needed to operate safely.

These horizontal and diagonal supports set column spacing and must be designed around the length and weight of your goods. Get this right, and your cantilever rack will stay steadfast, even when stacked to its limits.

Picking the right cantilever warehouse racking isn’t just about buying steel beams. It's about engineering a system that’s a perfect match for your products, your floor space, and your daily workflow. Get this right from the beginning, and you’ll save a lot of headaches down the track, improve safety, and just make life easier for your team. This planning stage is critical—a smart choice now will pay off for years.

The whole process starts with a good, hard look at what you’re actually storing. From there, you just need to match those needs to the physical layout of your warehouse and the forklifts you use every day.

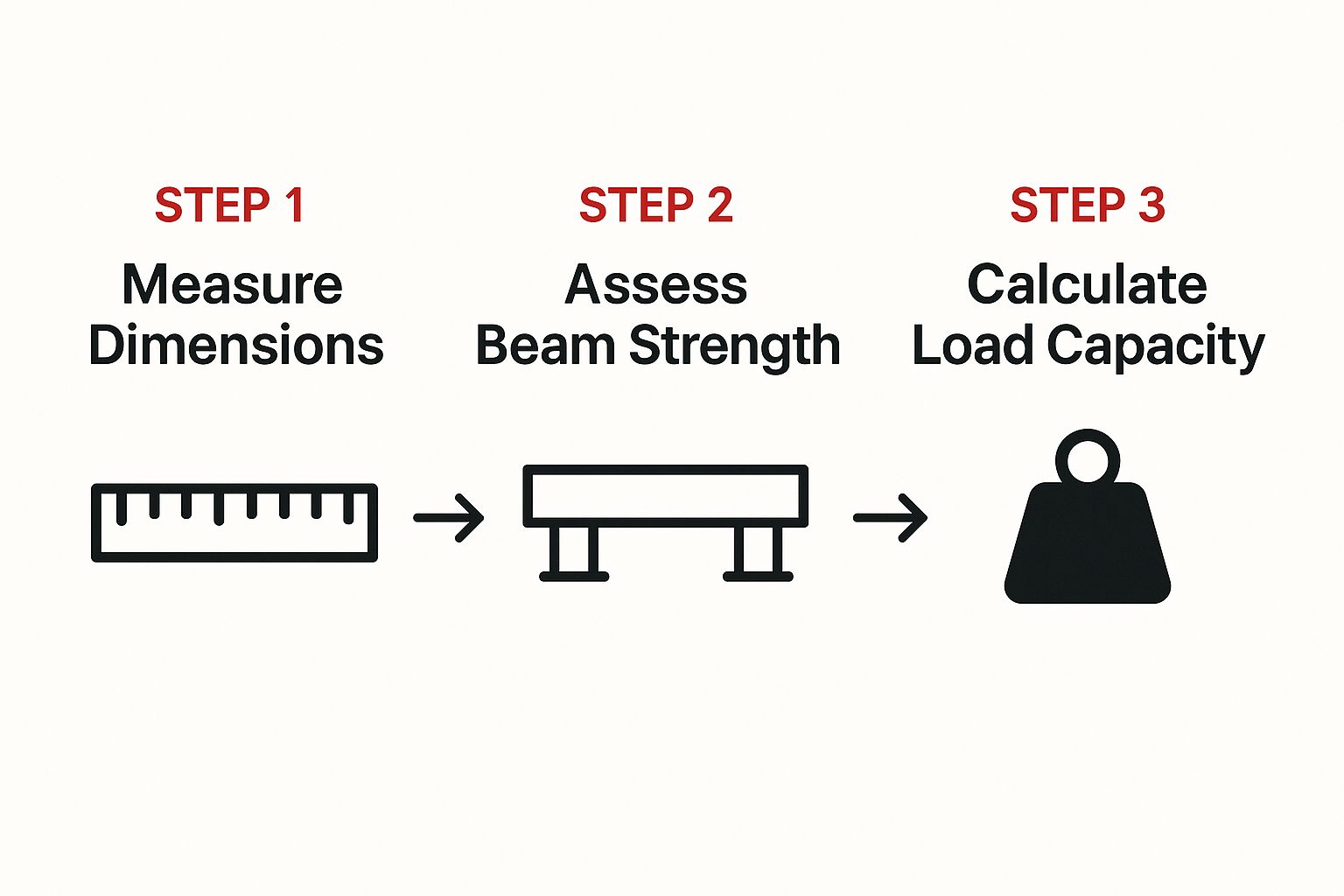

This infographic breaks down the basic steps for figuring out your cantilever racking needs—from measuring your products right through to calculating the final load capacity.

As you can see, it's a logical flow: start with the goods, figure out the strength needed for each component, and then confirm the total capacity to make sure everything is safe and efficient.

Before you even think about racking, you need to get forensic about what it’s going to hold. Start by making a list of the key specs for your longest, heaviest, and most awkward items.

For instance, a business storing 6-metre lengths of timber will need a different setup to one storing 4-metre steel bars. Always design your system around your biggest items to ensure it can handle everything in your inventory.

A classic mistake is planning only for today. Always build in a safety buffer. If your current stock weighs 800 kg per pack, design a system that can handle 1,000 kg. This gives you flexibility for new products or different suppliers in the future.

Once you’ve got a handle on your stock, it’s time to measure up your facility. The physical limits of your warehouse will dictate the final design and size of your cantilever racking.

Start with your ceiling height. This tells you the maximum height your uprights can be, letting you make the most of your vertical space. Just don’t forget to factor in clearance for sprinkler systems, lighting, or any overhead cranes.

Next, map out your available floor area. This will help you figure out how many rows of racking you can fit while leaving enough room for forklifts, loading zones, and pedestrian walkways. The type of forklift you use makes a huge difference here. A standard counterbalance forklift might need a 4-metre aisle, but a sideloader can work in a much tighter space, which means you can pack more racking in.

With all your product and warehouse measurements in hand, you can now get into the technical specs. This is where you match arm length, arm capacity, and column spacing to your specific loads.

In Australia, heavy-duty cantilever arms have specific load ratings. For example, a 900 mm arm can typically hold up to 1,500 kg, while a longer 1,200 mm arm might be rated for around 1,000 kg.

Let’s say you’re storing steel tubes that weigh 800 kg per pack. You could safely store four packs (a 3,200 kg total load) on one level using 900 mm arms, as long as the columns are spaced correctly—usually about 1,500 mm apart—to spread the weight evenly. For a deeper dive, you can check out some great insights on heavy-duty cantilever capacities at readyrack.net.au.

Making sure your final design meets Australian Work Health and Safety (WHS) standards is essential. And this is where getting some expert advice really pays off.

At Super Rack, we offer nationwide consultations to help you design the perfect solution. Our team can walk you through every calculation, making sure your system is not only efficient but 100% compliant and safe. We supply top-quality racking at competitive prices with fast delivery anywhere in Australia, making us the ideal partner for your storage needs.

Even the best cantilever warehouse racking system in the world is only as safe as its installation. Getting the assembly right isn't just a good idea—it's absolutely essential for the safety of your team, the integrity of your stock, and your compliance with Australian Work Health and Safety (WHS) regulations.

It all starts with the foundation. Your warehouse floor needs to be a solid, level concrete slab that can handle the massive point loads coming down through each base plate. If the concrete has cracks, slopes, or weak spots, the entire rack’s stability is compromised from day one.

When it comes to assembly, precision is non-negotiable. Every bolt must be tightened to spec, and every brace perfectly aligned to create a single, rigid structure. There's no room for shortcuts here; the consequences are just too serious.

Follow this practical checklist for a safe installation and ongoing peace of mind:

Once your racking is up, the job isn't done. Safety is an ongoing commitment that relies on regular inspections and proper team training to keep your workplace safe and get the most life out of your investment.

A well-maintained rack is a safe rack. Proactive checks for wear and tear can prevent minor issues from escalating into major structural failures, protecting both your people and your products.

Set up a routine inspection schedule to hunt for common problems. You’re looking for bent arms, signs of rust, loose bolts, or any dings from forklift impacts. If you find a compromised component, it needs to be unloaded and replaced immediately. Just as important is training your team on how to load and unload correctly—placing items evenly across the arms and avoiding hard impacts.

While a DIY installation might look like a way to save a few dollars upfront, the risks are far too high. Bringing in the professionals is the smartest move you can make. The Super Rack team provides expert, accredited installation services across Australia, guaranteeing your system is assembled correctly and complies with all WHS standards. To learn more, check out the details on our professional pallet racking installation services, which follow the same strict safety protocols.

For a solution that’s safe, efficient, and compliant from day one, let our experts handle the installation. Contact Super Rack today for a chat and discover the confidence that comes with a professionally installed system.

Choosing the right cantilever warehouse racking is a big decision. But the supplier you partner with is just as important as the steel itself. You need a solution that’s durable, cost-effective, and backed by people who actually know what they’re doing. This is where Super Rack stands out.

We build our racking systems from premium-grade steel, full stop. Every single component—from the baseplates to the arms—is engineered for maximum strength and a long service life. This commitment means your investment is safe, compliant, and ready to handle the daily grind of a busy Aussie warehouse.

But top-tier quality doesn’t have to break the bank. We offer highly competitive AUD pricing on our entire range, making professional-grade storage accessible for businesses of all sizes. Our goal is simple: deliver exceptional value that combines rugged durability with smart affordability.

A great product is only half the story. Super Rack backs Australian businesses with fast delivery right across the country and a nationwide service network that’s ready to help. From the first chat about design to professional installation and after-sales support, our team is with you every step of the way.

The need for smart storage is booming. The global cantilever rack market hit USD 1.24 billion in 2023, and with Australian construction and manufacturing growing, so is the demand for systems that can handle timber, piping, and other long materials. You can find more details about the cantilever rack market at giiresearch.com. We provide the practical guidance needed to get it right.

At Super Rack, our advantage is clear. We combine tough, high-quality products with competitive pricing, fast nationwide delivery, and end-to-end expert support. It’s a complete storage solution you can trust.

Ready to find the perfect cantilever system for your business? Our team is on hand to provide a free, no-obligation quote and consultation. Let us help you design a storage solution that boosts your efficiency and safety.

Here are the answers to some of the most common questions we get about cantilever warehouse racking.

The weight capacity depends on the arm's length and thickness. As a general guide, a 900 mm heavy-duty arm can typically support up to 1,500 kg, while a longer 1,200 mm arm might be rated for around 1,000 kg. However, the total capacity of the rack also depends on the upright columns and bracing. We always perform specific calculations to ensure your setup is safe and meets all WHS standards.

Yes, you can, but it needs to be properly protected against the weather. For outdoor use, hot-dip galvanised steel is essential. This coating creates a tough barrier against rust and corrosion, which is crucial for standing up to Australia's harsh conditions. A galvanised system will last much longer and require less maintenance over its life.

The aisle width is determined by the type of forklift you use. A standard counterbalance forklift usually needs 3.5 to 4.5 metres of space to manoeuvre safely. However, if you use a sideloader or multi-directional forklift, you can reduce the aisle width to around 2.5 metres, allowing you to fit more racking into the same floor space.

Upfront, cantilever racking can have a higher initial cost than standard pallet racking. This is because it often uses heavier-grade steel to provide the necessary strength without front columns. However, for storing long or bulky items, the return on investment can be significant. By improving handling efficiency, you can often achieve 20–30% faster operations, which saves on labour costs and boosts productivity over time.

Regular checks are vital to keep your racking safe and in good condition. We recommend a simple inspection schedule:

Ready to boost your warehouse productivity with high-quality cantilever warehouse racking? Contact Super Rack for a free, no-obligation quote and tailored design advice. Experience fast Australia-wide delivery, expert support and competitive AUD pricing. Visit Super Rack to get started today.

4000 to 4182

4186 to 4207

4300 to 4305

3000 To 3096

3098 To 3112

3114 To 3138

3140 To 3157

3161 To 3198

3200 To 3207

Let's connect