A business storage solution is much more than just a few shelves shoved against a wall. It’s a smart system, designed to organise, protect, and make your entire inventory easy to find and access. Think of it as the central nervous system for your whole operation—it’s what separates a chaotic, inefficient space from a streamlined, profitable one.

For many Aussie businesses, especially those dealing with the pressures of e-commerce growth and sky-high rent in the cities, a smart storage setup isn’t a luxury. It’s an absolute necessity for survival and growth.

This system is the engine that powers your operation. And just like any high-performance engine, it needs the right parts working together to be powerful and efficient. Without a proper system, you’re not just disorganised; you’re losing money through wasted time, damaged stock, and paying for space you aren’t even using properly.

In cities like Sydney and Melbourne, commercial rent can be a massive overhead. A well-designed storage solution lets you start thinking vertically, making use of the full height of your space instead of just spreading everything out on the floor.

Suddenly, you can store more products in the same footprint. This effectively slashes your storage cost-per-item and is crucial for any business wanting to scale up without the headache and expense of moving. It turns your existing space into a much more productive asset.

“A well-implemented storage solution is a direct investment in your business’s productivity. It transforms a fixed cost—your rent—into a dynamic asset that actively supports operational efficiency and profitability.”

A common mistake is treating storage as just another purchase. But a truly strategic solution is a system built around your specific needs. It’s about looking at your workflow, the types of stock you handle, and your business goals to build a setup that actually makes things run better.

To get a sense of how specialised modern storage systems are, it helps to look at innovations in other sectors. For instance, understanding What Is an Energy Storage System (ESS) shows how complex systems are designed to optimise a resource. Just as an ESS optimises power, the right warehouse system optimises your physical space and workflow.

Trying to find the right storage solution can feel like a puzzle with a thousand pieces. It’s easy to get lost in technical terms and specs, but understanding the main types of warehouse storage is the first step toward creating an efficient, organised space. Each system is designed to solve a specific problem, whether you’re dealing with heavy pallets, small parts, or those awkwardly shaped items that just don’t fit anywhere.

Let’s cut through the jargon and look at the most effective and popular systems out there. By using practical, real-world examples, you’ll see how each type of storage actually works and figure out which one is the best fit for your business. It’s time to transform that cluttered space into a streamlined operational hub.

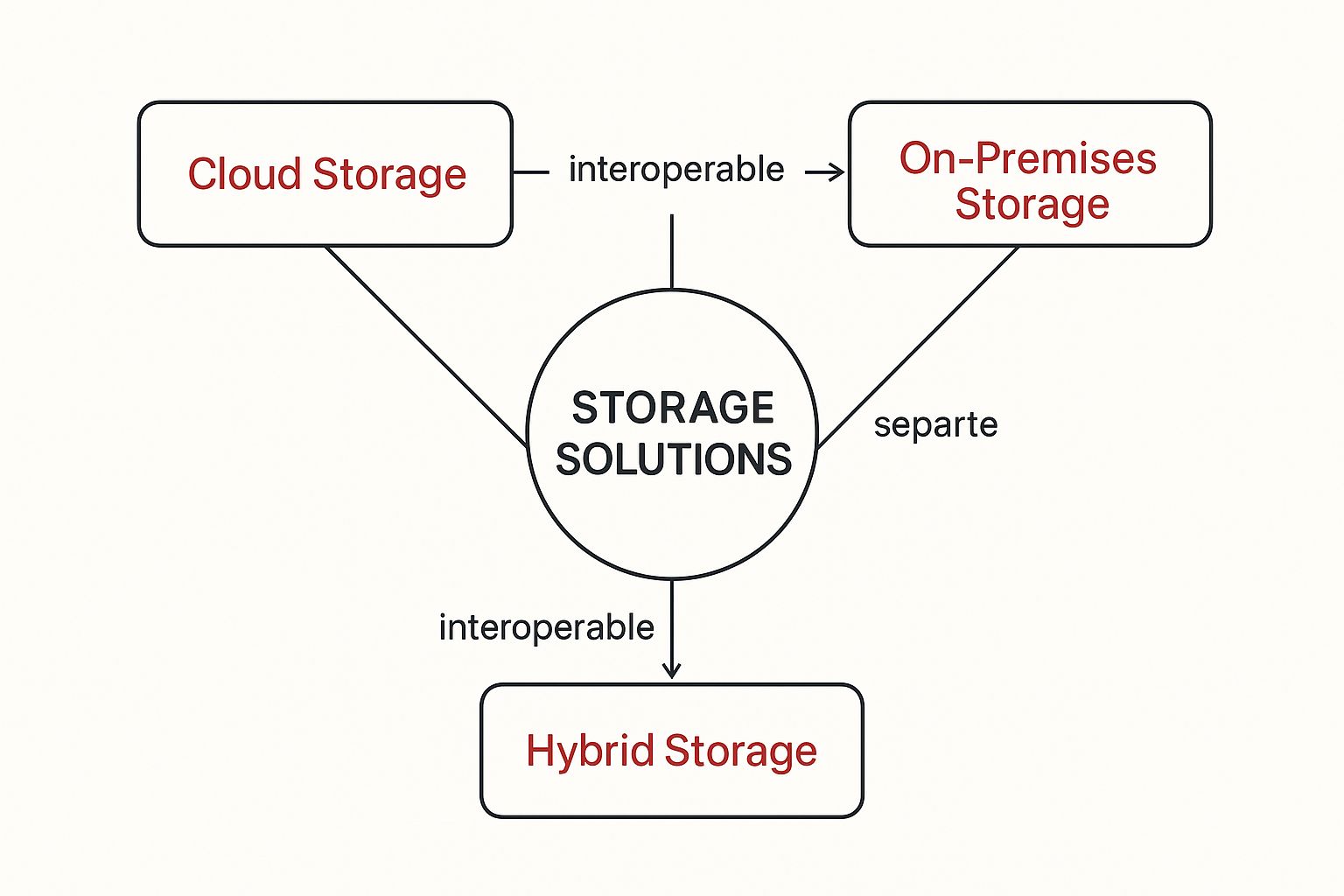

This concept map gives you a bird’s-eye view of modern storage, from physical warehouse systems to digital cloud infrastructure.

The visual shows how different storage types can connect, highlighting that a truly effective strategy often involves a mix of solutions tailored to specific business needs.

When you picture a warehouse, chances are you’re thinking of rows and rows of pallet racking. It’s the undisputed workhorse for any business that moves goods in bulk on pallets. This system is all about strength, stability, and making the most of every vertical metre you’ve got.

For example, take a beverage distributor in Western Sydney. They handle thousands of pallets of soft drinks and bottled water every single day. Without a solid storage plan, their warehouse floor would be an impassable maze. By installing pallet racking, they can stack pallets several levels high, keeping the floor clear so forklifts and staff can move safely and efficiently.

This vertical approach instantly multiplies their storage capacity without needing to find a bigger building. For businesses like this, pallet racking isn’t just a nice-to-have; it’s essential. The quality of the steel is crucial, too. At Super Rack, our systems are made from superior-grade steel, ensuring they can handle heavy loads safely for years. To make sure your setup is both safe and efficient, check out our guide on professional pallet racking installation.

Of course, not all stock arrives neatly stacked on a pallet. Many businesses, particularly in e-commerce, are juggling a huge variety of smaller, individual items that need to be picked by hand. This is exactly where Longspan shelving shines.

Think of an online clothing retailer based in Melbourne. Their stock is everything from t-shirts and shoes to accessories, all in different sizes and colours. Pallet racking would be total overkill. Longspan shelving is the perfect fit, offering wide, open shelves that staff can easily access on foot.

This system lets them organise products logically, which makes the whole order-picking process faster and more accurate. And because Longspan is modular, they can easily adjust shelf heights to fit new product lines—from tall boxes of boots to small bags of jewellery. That flexibility makes it the go-to solution for any business needing easy manual access to their goods.

The key to an efficient warehouse isn’t just storing items, but making them easily retrievable. The right system reduces picking time, which is a critical factor in customer satisfaction and operational cost.

So, what do you do with items that are too long or bulky for standard shelves or pallets? Businesses in construction, timber, or manufacturing run into this problem all the time. Storing long lengths of timber, steel pipes, or furniture can be a logistical nightmare without the right gear.

Cantilever racking is the specialised answer for these awkward items. It uses a sturdy central column with arms extending outwards, creating an open, unobstructed shelf. With no front supports in the way, loading and unloading with a forklift is a breeze.

Imagine a plumbing supplier in Brisbane. They need to store PVC pipes and steel tubing of various lengths, some stretching over six metres. Piling them on the floor is messy, unsafe, and makes finding the right piece nearly impossible. Cantilever racking lets them stack these long items horizontally, keeping them organised, off the ground, and ready to go. This specialist storage solution turns a potential hazard into a tidy, efficient system.

As you explore different storage options, remember that a well-organised system does more than just improve workflow. It can also be a key part of your strategies to reduce shrinkage by keeping inventory secure and accountable.

Choosing the right storage solution is a critical business decision that will directly impact your day-to-day operations. By understanding the core strengths of each type—pallet racking for bulk goods, Longspan for hand-picked items, and cantilever for long materials—you can make an informed choice. Super Rack provides expert advice and nationwide service, ensuring you get a high-quality, competitively priced system delivered fast, no matter where you are in Australia.

Picking the perfect storage solution for your business can feel like a huge task, but it doesn’t have to be. If you break it down and ask a few key questions about your space, your products, and your daily operations, you can find a system that not only works today but grows with you tomorrow.

A well-chosen storage system isn’t just another expense. It’s a direct investment in your operational efficiency. It dictates how fast you fulfil orders, how safe your team is, and how much value you get out of every square metre of your commercial lease. This guide will walk you through the essential steps to make a smart, informed decision.

Before you even start browsing racking types, get out the measuring tape. Seriously. Understanding your available space is the first and most critical step. Don’t just measure the floor—look up. The vertical space in your warehouse is often your most valuable, underused asset.

This initial check gives you the basic blueprint for a layout that maximises storage without creating a cramped, hazardous workspace.

Next up, take a good, hard look at what you’re actually storing. The size, weight, and shape of your products will have a huge say in what storage solution is best. A one-size-fits-all approach almost never works.

Imagine an online retailer selling outdoor gear. They might stock bulky kayaks, heavy cast-iron cookware, and small, light bags of climbing chalk. Each of those products demands a different storage method to keep them safe and easy to access. A smart combination of cantilever racking for the kayaks and versatile shelving and storage units for the smaller items would be far more effective than trying to jam everything into one type of system.

The right storage solution is designed around your inventory, not the other way around. Matching the system to your product mix is fundamental to creating an efficient and safe warehouse environment.

How do goods actually move through your warehouse? Tracing the journey from the receiving dock to the dispatch area is essential for designing a layout that just makes sense. The goal is always to minimise travel time and handling for your team.

Start by asking these key questions:

Thinking ahead is particularly important given what’s happening in the market. Across Australia, the demand for flexible commercial storage is climbing, driven by small and medium businesses that need adaptable spaces. Projections show that business use of storage facilities is expected to grow, highlighting the need for solutions that can scale.

By planning for expansion from day one, you build a foundation that can evolve with your business. It ensures your initial investment continues to pay off for years to come.

Finally, never underestimate the value of a professional opinion. You know your business inside and out, but a storage expert brings specialised knowledge of different systems, layout optimisation, and critical safety compliance.

At Super Rack, our team has helped countless Australian businesses design and implement customised layouts. We provide practical, expert advice to ensure you get a high-quality, competitively priced storage solution that’s a perfect fit. With fast delivery and nationwide service, we’re here to help you create a safer, more efficient, and more profitable workspace.

Ever wondered why getting your storage right has suddenly become a top priority for so many Aussie businesses? It’s not just about being tidy. It’s a direct reaction to big economic shifts that are changing how we all buy, sell, and manage our stock.

Two major forces are at play: the non-stop growth of e-commerce and the ever-tightening squeeze on commercial real estate, especially in our major cities. These two factors have created a perfect storm where smart, well-planned storage isn’t just a nice-to-have—it’s a must-have. Understanding these trends makes it clear why investing in the right system is such a smart move.

The explosion of online shopping has completely changed the game for warehouses and distribution centres. The pressure is on like never before to handle more products, more variety, and get orders out the door at lightning speed.

A messy, disorganised warehouse just can’t keep up. Simple as that. When your team is wasting precious minutes hunting for an item, order times blow out, and you end up with unhappy customers. A smart storage setup, like combining pallet racking for bulk stock with accessible longspan shelving for hand-picking, makes the whole process smoother. It creates a logical flow that makes finding, picking, and dispatching orders faster and more accurate.

At the same time, the price of commercial floor space in cities like Sydney and Melbourne just keeps climbing. Land is limited, so businesses are being forced to do more with less. Those sprawling, single-level warehouses are quickly becoming an expensive luxury.

This is forcing businesses to start thinking vertically. By installing tall racking systems, you can literally multiply your storage capacity without needing a bigger building. It’s a practical, direct answer to rising property costs, letting you squeeze every drop of value from the square metres you’re paying for.

This isn’t just a commercial problem; it’s hitting personal storage too. The Australian self-storage market was worth a massive $1.2 billion AUD in 2024. With 86.6% of Aussies now living in urban areas with less space at home, the demand is only growing. You can read more about this trend and its impact on the Australian self-storage market.

Investing in a vertical storage solution is one of the most effective ways to combat rising commercial rents. It allows you to increase your inventory capacity and operational output without the massive cost of relocating to a larger facility.

When you boil it down, these economic pressures are pushing Australian businesses to get smarter and more efficient. A well-designed storage system from Super Rack is the direct answer. We provide the expert advice and quality systems to help you turn these challenges into real opportunities, all backed by competitive prices and fast, nationwide delivery.

The most efficient warehouses don’t just have one type of storage. They operate like a finely tuned ecosystem, where different systems work together to create a seamless flow of goods. It’s about moving beyond individual products and designing a complete solution that transforms your whole operation.

A truly integrated system is more than just finding a home for your stock. It’s about building a smart layout that actively boosts your speed, accuracy, and safety. When you get this right, your physical space stops being an overhead and starts being a powerful competitive advantage.

The real secret to a high-performance warehouse is mixing and matching different storage types to handle specific jobs. Each system has a unique role, from the moment goods arrive to the second they’re dispatched.

A classic—and incredibly effective—combination is using heavy-duty pallet racking for bulk storage alongside easy-access longspan shelving for order picking. In this setup, full pallets are loaded into the high-density racking. As needed, smaller quantities are then moved to the longspan shelving, where staff can quickly and easily pick individual items by hand to fulfil customer orders.

This “bulk-to-pick” model creates a logical, organised workflow that cuts down on congestion and makes the whole fulfilment process dramatically faster.

A smart layout is built on a few core principles that all come down to safety, accessibility, and speed. Nailing these fundamentals is the key to creating a system that doesn’t just hold your stock but actually makes your team more productive.

Here’s what matters most:

A well-designed warehouse layout is the foundation of operational excellence. It transforms a static storage space into a dynamic environment that supports every stage of the fulfilment cycle, from inventory management to final dispatch.

An integrated warehouse doesn’t exist in a bubble. It’s a critical link in your wider supply chain, connecting how you manage inventory with your logistics and transport operations. When you get your internal storage and workflow right, you create a far more reliable and efficient link in that chain. To learn more, understanding the key benefits of a Transportation Management System (TMS) shows how these pieces fit together.

This level of integration is becoming more important than ever. Australia’s warehouse and storage sector is changing fast, largely driven by the boom in e-commerce and new logistics technologies. Businesses are now laser-focused on supply chain efficiency to meet ever-faster delivery expectations. This has put a spotlight on the need for organised spaces where products are stored properly to ensure every order is fulfilled on time, every time.

Designing and setting up a fully integrated warehouse system is a big job that requires real-world expertise. From calculating load capacities to making sure everything complies with Australian safety standards, getting it right from the start is essential.

At Super Rack, our team is here to give you the expert advice you need to design an effective storage solution. We take the time to understand your unique workflow, inventory, and growth plans to create a customised layout that gets the most value out of your space. With top-quality products, competitive pricing, and fast nationwide delivery, we’re your partner in building a smarter warehouse. To learn more, check out our guide on the importance of professional pallet racking installation.

Alright, you’ve done the research and now understand the different types of racking and shelving available. The next step is turning that knowledge into a real-world system that makes your business run smoother.

It all starts with a clear plan. You need to properly measure your space, get a handle on your inventory’s specific needs, and think about where your business will be in a few years. Nailing these details is the key to a successful setup. A great storage system doesn’t just hold your goods—it actively improves how you get things done.

The journey to a more efficient business begins with a single, decisive step. Investing in the right storage solution is an investment in your productivity, safety, and future success.

The Super Rack team is here to help you bridge the gap between planning and doing. Our experts can offer practical, no-obligation advice to help design the perfect system for your exact needs. Backed by our commitment to quality, fair pricing, and fast nationwide delivery, we’re ready to help you build a smarter, more productive workspace.

Ready to get started? Contact our expert team today or explore our range of high-quality racking and shelving.

When you’re ready to invest in a new storage system, it’s normal to have a few questions. Getting clear, practical answers is the best way to feel confident you’re making the right call. Here, we tackle some of the most common queries we get from businesses choosing their perfect storage solution.

This is a big one, and getting it right is vital for safety. Start by working out the total weight of your heaviest pallet, or the combined weight of all the items you plan to load onto a single shelf.

Once you have that number, you’ll want to choose a system with a load rating that safely exceeds it. Think of it as a crucial safety buffer. At Super Rack, all our products have clearly stated weight capacities, and our team can help you analyse your stock to recommend the safest and most effective solution.

While simpler systems like our Longspan shelving are designed for straightforward DIY assembly, pallet racking is a different beast entirely. We always recommend professional installation.

Why? Because correct assembly by experienced installers is critical for the system’s structural integrity. It’s also the only way to guarantee it complies with Australian safety standards. To make sure your new storage is set up safely and works perfectly from day one, Super Rack offers professional installation services right across the country. It gives you complete peace of mind knowing the job’s been done right.

Thinking ahead is just smart business. The best way to prepare for growth is to choose a modular system that can be easily expanded down the track.

For example, you could start with just a few bays of pallet racking but design the initial layout with enough empty space to add more as your inventory grows. Sometimes, investing in a system that slightly exceeds your immediate needs is a very wise long-term strategy. Our team specialises in creating scalable storage plans that grow with you, ensuring your investment continues to pay off for years to come.

At Super Rack, we’re here to provide expert advice and high-quality systems to help you build a safer, more efficient workspace. Backed by competitive pricing and fast, nationwide delivery, we’re your partner in getting your operations sorted.

Explore our full range of storage solutions and find the perfect fit for your business at https://www.superrack.com.au.

4000 to 4182

4186 to 4207

4300 to 4305

3000 To 3096

3098 To 3112

3114 To 3138

3140 To 3157

3161 To 3198

3200 To 3207

Order Delays for Temporary Fencing, Agricultural Products, Pallet Racking, Cantilever Racking and Mesh Panels

Let's connect