Think of fence panels mesh as see-through, pre-built walls made from tough steel wire. For Aussie businesses needing a barrier that’s strong, reliable, and transparent, these panels are the go-to solution. Unlike solid fences, they give you clear visibility while still being a serious physical deterrent.

At its heart, a mesh fence panel is a grid of interlocking steel wires, all welded together to create a rigid structure. These grids are then framed into individual panels you can join together quickly and easily. It’s this modular design that’s made them so popular with tradies, construction site managers, and warehouse operators across Australia.

Instead of building a fence from scratch on-site—a slow and labour-intensive job—these pre-made panels are a plug-and-play solution. This approach slashes installation time, saving you real money and headaches on any project.

The perks of using a mesh fencing system go well beyond a quick setup. For any business owner, the benefits hit on safety, security, and the bottom line.

Here’s what you get:

It’s easy to see how this works in the real world. A project manager for a new commercial build can throw up a temporary mesh fence around the entire site in a single day. Just like that, they’ve established a safe work zone and protected thousands of dollars in tools and machinery from overnight theft.

The real value of fence panels mesh is in its simplicity and effectiveness. It delivers a high level of security without the cost or complexity of older fencing methods, making it a smart investment for any commercial or industrial site.

Here at Super Rack, we know that reliability is non-negotiable. That’s why we’re focused on providing top-quality mesh panels built to handle tough Aussie conditions. With our competitive pricing and fast, nationwide delivery, securing your site is straightforward and efficient. When you’re ready to lock down your property, our team is here to offer expert advice and help you pick the perfect security fencing solution for your needs.

When you start looking at fence panels mesh, you’ll quickly find it’s not a one-size-fits-all solution. Picking the right type is crucial for getting the security and longevity you need for your project. The main differences boil down to how the mesh is built and what it’s coated with, and each combination is suited for different jobs.

Getting your head around these options helps you avoid common stuff-ups. You don’t want to overspend on a panel that’s overkill for a simple job, or worse, choose one that isn’t tough enough for a high-security site. It’s all about matching the product to the purpose.

Welded wire mesh is the tough guy in the fencing world. It’s made by fusing steel wires together at every single intersection, creating an incredibly strong and rigid panel. This solid construction makes it extremely difficult to cut or bend.

Because of this strength, welded wire mesh is the go-to choice for permanent, high-security applications. Think about locking down a data centre, a logistics hub full of high-value goods, or a permanent equipment compound. In these spots, preventing any breach is the top priority, and the unyielding structure of welded panels delivers that peace of mind.

Chain-wire mesh, which you probably know as chain-link, is woven together in a classic diamond pattern. This method gives it a flexibility that rigid welded panels don’t have, making it a fantastic option for covering large or uneven ground.

It’s a practical and cost-effective way to secure big perimeters like storage yards, mark out boundaries for temporary event sites, or section off areas of a construction zone. While it’s not as rigid as its welded counterpart, it still provides a reliable and visible barrier that gets the job done efficiently over long distances.

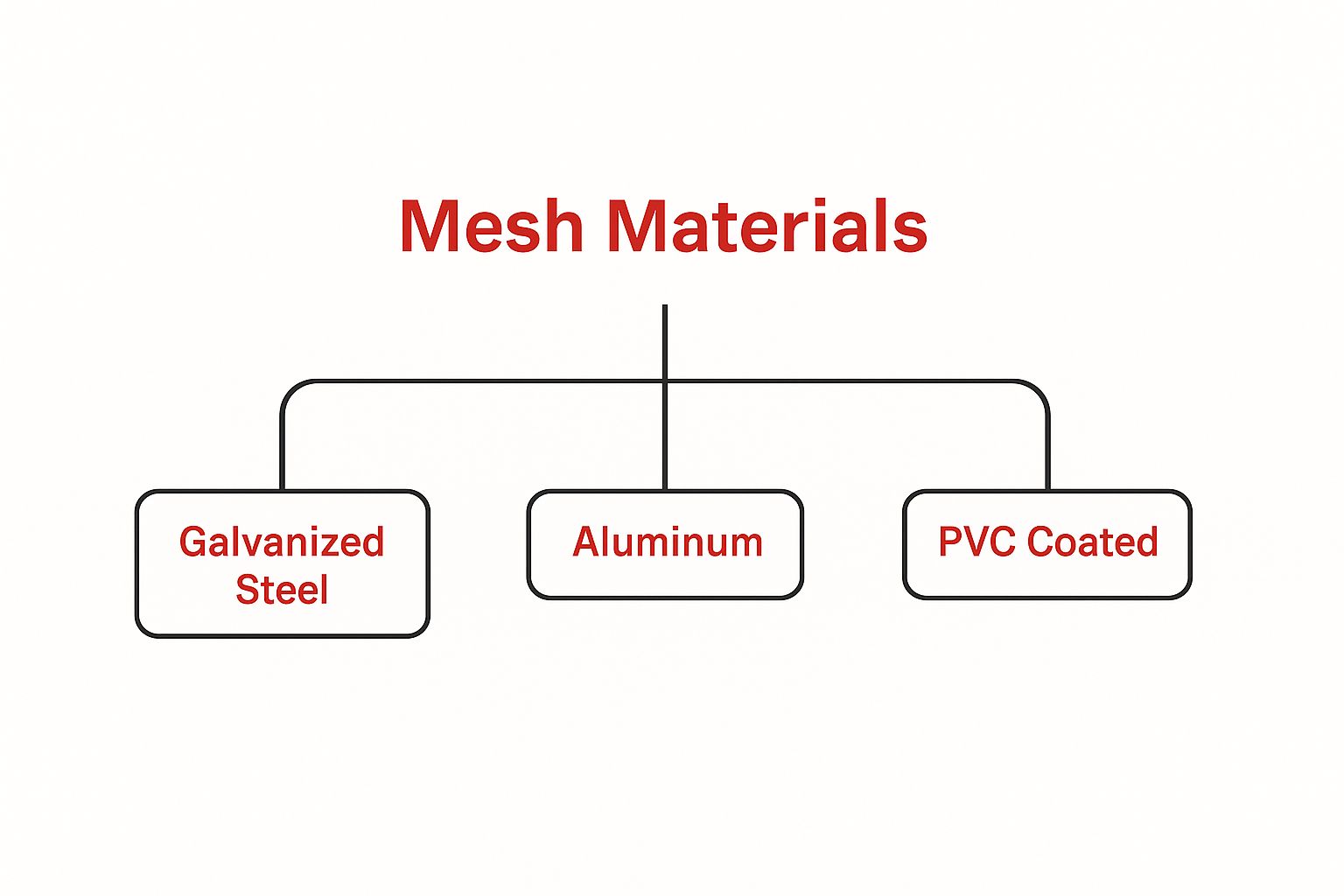

The material and its coating are just as important as the way the panel is built. This protective layer is what shields the steel from Australia’s often harsh weather, from corrosive coastal salt spray to intense UV rays.

This quick guide breaks down the most common material and coating options.

The key thing to remember is that each finish offers a specific type of protection, which directly impacts the panel’s lifespan and how it looks over time.

Here’s a closer look at what these coatings actually do:

Choosing the right type of mesh panel isn’t just about security; it’s about long-term value. A heavy-duty, galvanised welded panel might cost more upfront but will save you money on replacements for a permanent site. For a temporary boundary, a cost-effective chain-wire solution is often the smarter financial move.

At Super Rack, we offer superior-quality security fencing solutions with finishes designed to last. Our team can provide expert advice to help you select the perfect panel for your project, backed by competitive pricing and fast, nationwide delivery.

Ever wondered why one mesh fence panel stands strong for decades, while another starts showing rust in just a few years? It all comes down to the quality of the materials and, just as importantly, the protective finishes applied to them. Getting this right is the key to making a smart, long-term investment rather than just picking the cheapest option off the shelf.

The foundation of any decent panel is high-grade steel. But let’s be honest, steel on its own doesn’t stand a chance against Australia’s harsh sun and relentless rain—it’s prone to rust. This is where protective coatings come in, acting as a crucial shield against corrosion and environmental wear and tear.

Galvanisation is the go-to process for protecting steel, involving a coating of zinc to stop rust in its tracks. A hot-dip galvanised finish is the gold standard for fencing. It’s not just a layer of paint; it creates a thick, resilient barrier that molecularly bonds to the steel. The result is a tough-as-nails defence that can handle scratches, moisture, and UV exposure for years on end.

This process is absolutely essential in coastal areas or humid regions where the salty air can literally eat away at unprotected metal. A properly galvanised panel isn’t just a purchase; it’s an asset built for longevity.

For an even higher level of durability and a cleaner, more professional look, some panels get an extra coating on top of the galvanisation.

These additional layers don’t just extend the life of the fence; they also improve its appearance, which can be a big deal for commercial properties where presentation matters.

The true value of a fence panel isn’t its sticker price—it’s the total cost over its entire lifespan. Investing in a panel with superior coatings from a trusted supplier like Super Rack means fewer repairs, less maintenance, and a much longer service life. That’s real money saved down the track.

Beyond coatings, two other specs have a massive impact on a panel’s strength: wire gauge and aperture size.

Wire gauge is all about the thickness of the steel wire—and here’s the tricky part: a lower gauge number means a thicker, stronger wire. For anything high-security, a thick wire is non-negotiable. The aperture is simply the size of the holes in the mesh. Smaller apertures make a panel incredibly difficult to climb or cut through, which is a huge security advantage. These details are just as important as the finish, especially if you’re protecting valuable assets or building a secure rural enclosure.

The demand for quality welded mesh is on the rise, and for good reason. It’s a specialised market in Australia now valued at around USD 33 million, a figure that jumped by 32% in a single year. This growth shows just how much Aussie businesses are relying on these durable fencing options for commercial and industrial security. To get a better sense of this trend, you can find more insights on IndexBox.

Let’s move from theory to practice and see how Aussie businesses put fence panels mesh to work every single day. The sheer versatility of these systems means they solve real security and safety challenges across countless industries, from major construction projects to bustling logistics hubs.

Take a busy city construction site. Temporary mesh panels can be thrown up in no time to create a secure perimeter. This one simple action achieves two critical goals: it keeps the public safely away from potential hazards and protects thousands of dollars worth of equipment and materials from overnight theft.

Now, picture a large-scale warehouse or a distribution centre. For these operations, a heavy-duty welded mesh fence is the go-to solution for guarding the entire boundary. Its rigid structure is a powerful visual deterrent against break-ins, while the see-through design gives security cameras and guards a clear line of sight right across the property.

The real strength of mesh fencing is its adaptability. It’s not just a perimeter barrier; it’s a tool for creating secure, organised, and safe zones within any commercial or industrial environment.

This flexibility isn’t just for the property line, either. Many businesses use mesh panels internally to solve specific problems.

Here are a few common examples you’ll see on the ground:

The specific features of the fence panels mesh are what make them so effective. For a high-security area, a panel with a small, anti-climb aperture gets the job done because it’s nearly impossible to get a foothold or handhold. For a site boundary next to a busy road, a panel with proven impact resistance is the logical choice to withstand any accidental bumps.

The growth in this sector speaks for itself. The Australian commercial and industrial fencing market was valued at around AUD 985.10 million and is expected to nearly double by 2034, driven by rising security concerns across factories, warehouses, and construction sites. You can read the full market forecast on Research and Markets to dig into the details.

This versatility even extends to smaller-scale needs, where something like a modular mesh panel can be used for creating custom enclosures. At Super Rack, we provide superior quality fencing solutions made for these real-world applications. With our competitive pricing and fast nationwide delivery, securing your site has never been easier.

Choosing the right fence panels mesh can feel like a big decision, but it gets a whole lot simpler when you know what to ask. By running through a few key questions before you buy, you can make a smart investment that fits your needs perfectly, both today and down the track.

Think of this as your decision-making toolkit. It’s all about looking at your specific site and challenges to find the perfect match, ensuring you get the best possible value and performance out of your fence.

Before you even start browsing products, grab a notepad and work through these essential questions. Your answers will point you straight to the right solution.

These points are especially important as the Australian commercial fencing market continues to grow. Temporary solutions, in particular, are becoming a key trend for securing materials and managing crowds. This market is part of a larger industry valued at around USD 321.97 million, and it’s projected to keep expanding.

It’s easy to get fixated on the initial purchase price, but the true cost of a fence is measured over its entire lifespan. A cheaper, lower-quality panel might save you a few dollars today, but it could end up costing you thousands in maintenance and early replacement costs down the line.

Investing in a superior panel with a high-quality coating from a trusted supplier like Super Rack is the smarter financial decision. It ensures you get the best value over the long haul, not just the lowest upfront price.

When you’re mapping out your fencing project, getting the budget right is critical. Using online tools that help you predict construction material costs can be invaluable for accurate financial planning, keeping your project on track.

At Super Rack, our focus is on providing durable, high-quality fence panels mesh that delivers security you can count on for years. With our competitive pricing, expert advice, and fast nationwide delivery, we help you make an investment that truly protects your assets.

Getting your site security right comes down to one simple thing: choosing the right product from the right partner. As we’ve covered, quality fence panels mesh is a smart investment in safety and protecting your assets, but the supplier you choose is just as important.

At Super Rack, we make that investment a straightforward one. We focus on supplying superior-grade materials, properly engineered to handle tough Aussie conditions, so your fence stands strong for years to come. Our competitive pricing and fast, nationwide delivery also mean you can get your site secure on time and within budget.

Even more importantly, our team is here to offer practical, expert advice to help you cut through the options. We genuinely understand the specific challenges you face when securing construction sites, warehouses, and busy industrial yards. For a broader look at this topic, digging into comprehensive strategies for construction site security can offer some really valuable insights.

Choosing a partner for your security needs is about more than just a transaction. It’s about finding a reliable supplier who understands your project and provides a solution that truly protects your assets for the long haul.

When you’re ready to lock down your property, we’re here with a reliable solution you can count on.

Ready to find the right fencing for your project? Browse our range of security fencing online or contact our expert team today for practical advice tailored to your needs.

We get a lot of questions from business owners and site managers about mesh fence panels. Here are a few of the most common ones we hear.

A properly hot-dip galvanised mesh panel is a serious long-term asset. You’re not just buying a fence; you’re investing in years of security.

In most Australian environments, you can expect it to last for over 20 years without any significant rust popping up. If you’re right on the coast with constant salt spray, that might be a little less, but it will still give you decades of reliable protection. It’s an extremely cost-effective choice for securing your site.

For straightforward jobs like setting up basic site boundaries, plenty of tradies with the right gear and a bit of know-how can handle the installation themselves.

However, when it comes to permanent, high-security applications, we strongly recommend calling in the professionals. This ensures the footings are spot-on, the panels are perfectly aligned, and the entire fence meets all the necessary structural and safety standards.

It’s simpler than it sounds. Think of it like this:

Wire gauge is all about the thickness of the steel wire. The key thing to remember is that a lower gauge number means a thicker, stronger wire.

Aperture is just the size of the square or rectangular holes in the mesh. For top-notch security, you want a thick wire (low gauge) and small holes (small aperture). This combination makes the panel incredibly difficult to cut or climb.

Ready to secure your site with a reliable, long-lasting solution? At Super Rack, we provide superior-quality fencing backed by expert advice. https://www.superrack.com.au

4000 to 4182

4186 to 4207

4300 to 4305

3000 To 3096

3098 To 3112

3114 To 3138

3140 To 3157

3161 To 3198

3200 To 3207

Let's connect