Ever tried storing long lengths of timber, steel pipes, or bulky furniture on standard pallet racking? It’s often a recipe for inefficiency and can be downright unsafe. Cantilever racking systems are the purpose-built solution for this exact problem. They give you open-fronted, easily accessible storage for all those long, awkward, or irregularly shaped items that just don’t fit anywhere else.

What Exactly Is a Cantilever Racking System?

Picture a big, sturdy tree with strong branches reaching out from its trunk—that’s the basic idea behind a cantilever rack. Unlike traditional pallet racking, which has vertical beams at the front that get in the way, cantilever racks are completely open. This design makes loading and unloading long items with a forklift incredibly simple and safe.

This unique structure is a game-changer for warehouses and yards that handle unconventional stock. By getting rid of the front barriers, these systems allow direct access to the full length of your materials. This speeds up handling times and seriously reduces the risk of damaging products during storage and retrieval. It’s an engineered solution designed specifically for items that standard racking just can’t manage.

The Core Components Explained

A cantilever racking system is made up of several key parts that work together to create a rock-solid storage unit. Knowing what these components are helps make sense of how the system can support such heavy and awkward loads so effectively. Each piece plays a critical role in the rack’s overall strength and function.

The main components include:

- The Base: This is the anchor of the whole system. A heavy-duty steel base secures the structure to the floor, providing stability and stopping it from tipping over. It also doubles as the first storage level.

- Upright Columns: These are the vertical “trunks” of the rack. They are bolted firmly to the base and have holes running up their height, which lets you adjust the arms to different levels.

- Arms: These are the horizontal “branches” that stick out from the uprights to hold your stock. Arms can be straight or inclined and come in various lengths and load capacities to suit different materials.

- Bracing: Steel braces run diagonally and horizontally between the upright columns. They connect the columns, adding crucial rigidity and stability to the entire structure, especially for long runs of racking.

Why This Design Works So Well

The real genius of the cantilever design is its simplicity and unobstructed access. With no front column, there are no vertical obstacles to navigate when loading or unloading. This is a massive advantage for industries dealing with materials of varying lengths, like timber yards or steel suppliers.

For example, a forklift operator can easily place a 6-metre bundle of steel tubing onto the arms without having to manoeuvre around a front support beam. This doesn’t just make the process faster; it makes it significantly safer. The end result is a highly efficient, space-saving storage system that’s perfectly suited for items that would otherwise be left in hazardous stacks on the floor. Super Rack provides expert advice to ensure you get a system that perfectly matches your inventory and operational flow.

The Real Benefits of Using Cantilever Racking

It’s easy to think of cantilever racking as just another type of shelf, but it’s a seriously clever solution that delivers real, practical wins for any warehouse or yard dealing with bulky stock. It’s designed from the ground up to solve the common headaches of storing long, awkward goods, transforming cluttered floor space into an organised, efficient, and much safer environment.

The secret is its open-front design. By getting rid of the front vertical columns you see on standard pallet racks, it gives forklifts completely clear, unobstructed access. This simple but powerful feature is what makes cantilever racking a game-changer for businesses handling timber, steel pipes, or furniture packs, giving you a massive boost in productivity and letting you reclaim your floor space.

Maximise Your Storage Space

The most obvious benefit is how it lets you take advantage of vertical space. Cantilever racking turns all that unused air in your warehouse into valuable storage, letting you stack items high and tight. This means you can dramatically increase your storage capacity without the huge expense of expanding your building.

Instead of messy, unstable piles on the floor, you get neat, orderly rows that go straight up. This doesn’t just save space; it also makes it far easier to see what you’ve got and get to it, cutting down the time your team spends hunting for the right materials. It’s the smart way to get more from the space you already own.

Boost Operational Efficiency

When your forklift operators have clear, direct access to stock, handling times drop. Fast. With no front beams to manoeuvre around, loading and unloading long items becomes much quicker and simpler. This small saving in handling time on each item really adds up, leading to a significant jump in overall productivity.

Think about it: digging a specific bundle of steel out from the bottom of a floor stack is slow and frustrating work, often forcing you to move other stock first. With a cantilever rack, the driver can just lift the required bundle directly off the arms. This kind of efficiency is vital in Australia’s fast-paced industrial and retail sectors. You can read more about the importance of warehouse racking in the full market research to see just how crucial it is.

By providing a designated, secure home for bulky inventory, cantilever racking systems dramatically reduce the risk of product damage. Items are less likely to be bumped, scraped, or bent during handling, which protects your bottom line.

Unmatched Versatility and Flexibility

Your inventory needs aren’t static, so your storage system shouldn’t be either. The arms on cantilever racks are typically adjustable, which means you can reconfigure the levels to suit different product sizes and weights as your needs change. This makes it a future-proof investment for your business.

Whether you’re storing lightweight PVC pipes one month or heavy-duty steel beams the next, the system can be adapted to handle the job. This flexibility ensures your racking remains a valuable asset as your business grows and evolves.

Enhance Workplace Safety

Let’s be honest, floor stacks of long, heavy materials are a serious workplace hazard. They can be unstable, create trip hazards, and make the whole workspace feel chaotic and dangerous. A properly installed cantilever racking system, like those from Super Rack, gets rid of these risks completely.

By giving bulky items a stable and organised home, you create a much safer environment for your team.

- Prevents Accidents: It stops materials from toppling over from precarious stacks.

- Improves Visibility: Tidy, organised aisles give forklift operators clear sightlines.

- Reduces Strain: Easier access means less manual handling and repositioning of heavy items.

A well-designed cantilever racking system isn’t just about storage; it’s about building a safer, more productive workplace. At Super Rack, our systems are built with superior quality steel to stand up to the toughest Australian worksites, backed by expert advice and nationwide service.

Which Australian Industries Rely on Cantilever Racking?

While the theory behind cantilever racking systems is simple enough, seeing them in the wild is where their value really clicks. Across Australia, plenty of industries depend on these specialist racks to solve the headache of storing long, heavy, or just plain awkward inventory. From buzzing timber yards to high-tech manufacturing plants, cantilever racking is the unsung hero of safe, efficient storage.

The popularity of these systems is tied directly to Australia’s backbone industries. As our logistics, manufacturing, and building sectors have grown, so has the demand for smart storage. Cantilever racking is especially crucial for businesses handling bulky goods like timber, pipes, and steel sheets—materials that are the lifeblood of our construction and manufacturing landscape.

Timber Yards and Building Suppliers

Walk into any busy Aussie timber yard, and you’ll see rows of heavy-duty cantilever racks. Timber merchants juggle a massive variety of products, from long structural beams and laminated veneer lumber (LVL) to packs of decking. Trying to store this on the floor is a logistical nightmare.

Piling stock on the ground leads to damaged products, makes stocktakes nearly impossible, and creates serious safety hazards. Cantilever racking sorts out all these problems in one go.

- Prevents Warping: By supporting long lengths of timber at several points, the arms stop the wood from bowing and warping, protecting your investment.

- Improves Stock Access: A forklift operator can grab a specific pack of timber without having to shift a dozen others out of the way first. This massively speeds up order fulfilment.

- Organises Inventory: Different types and grades of timber can be separated onto different levels, making inventory management a breeze.

For a timber business, this organised system means faster service for tradies, less damaged stock written off, and a much safer yard for everyone.

Plumbing and Electrical Wholesalers

A plumbing supply wholesaler is another classic example of a business that gets a huge leg-up from cantilever racking. They need to stock kilometres of PVC and copper pipes, plus conduit and other long items that just don’t work on standard pallet racking.

By using cantilever racking systems, these suppliers can neatly organise their entire pipe inventory by diameter, material, and length. This makes it quick and easy for staff to pick orders for plumbers and sparkies who need to get back to a job site fast. A well-planned system, like those from Super Rack with our nationwide service and fast delivery, can turn a cluttered warehouse into a high-flow distribution hub.

Steel Fabricators and Manufacturing Plants

The manufacturing world runs on heavy, long raw materials. Steel fabricators, for example, have to store everything from enormous I-beams and RHS (Rectangular Hollow Section) steel to long bars of aluminium extrusion. Leaving these materials lying on the factory floor isn’t just inefficient; it’s a major safety risk.

Cantilever racking gives these heavy metal products a designated, secure, and easy-to-reach home. This keeps walkways clear, cuts down the risk of accidents, and protects valuable raw materials from damage.

For manufacturers, this level of organisation is key to keeping the production line moving smoothly. When a specific type of steel bar is needed, it can be found and retrieved in minutes, not hours. That efficiency boost goes straight to the bottom line, making a quality cantilever system a very smart investment.

Furniture and Homewares Wholesalers

It’s not just building materials that are a perfect match for cantilever racking. Furniture wholesalers use these systems to store bulky items like sofas, long flat-pack boxes, and rolled-up carpets. These products are often delicate and easily damaged if stacked the wrong way.

Placing them on sturdy cantilever arms prevents crushing and other damage, ensuring they reach retailers in showroom condition. It also provides excellent visibility for stock control, letting businesses see exactly what they have at a glance. For any business dealing with bulky, non-palletised goods, cantilever racking offers a practical and cost-effective way to get organised.

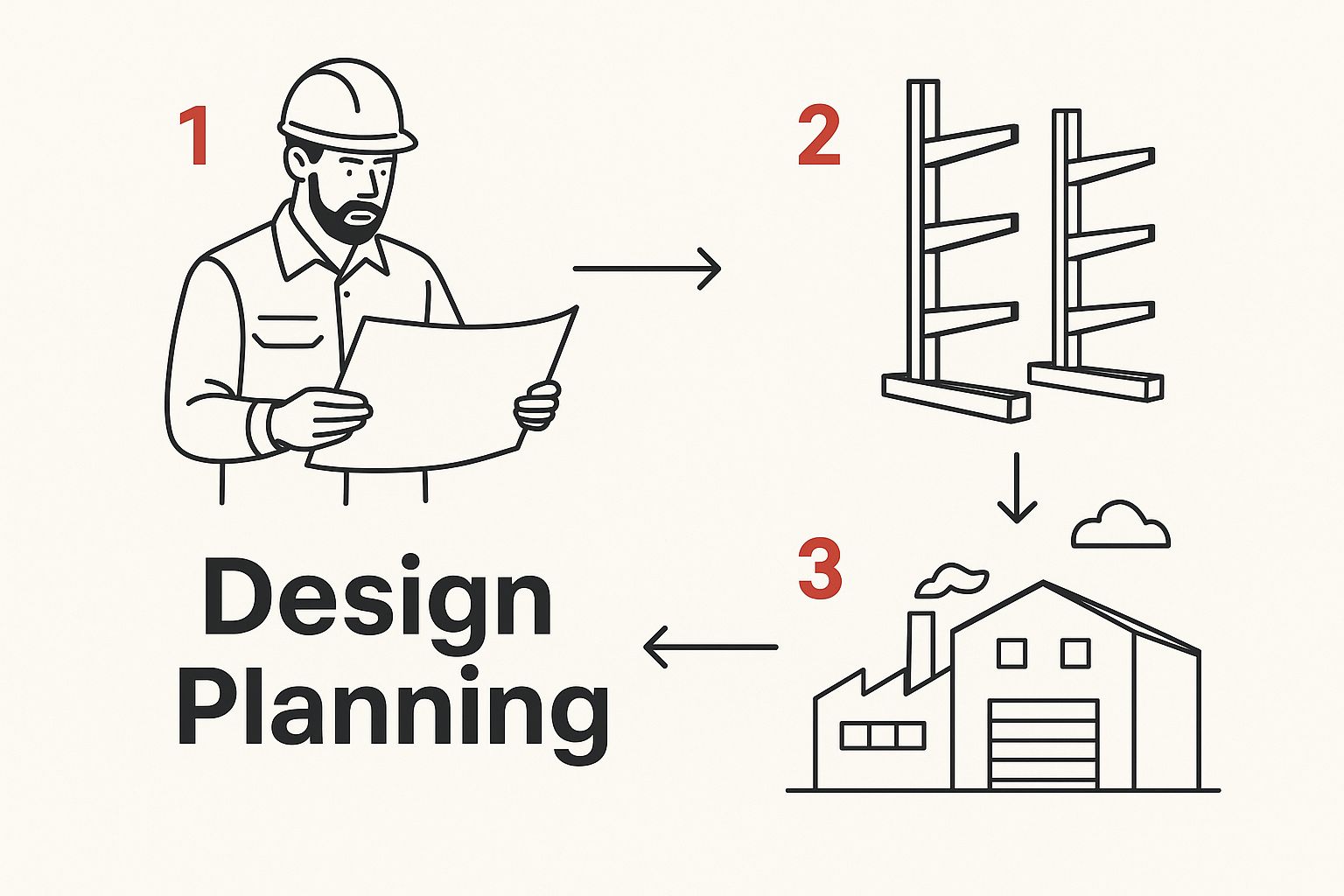

How to Design Your Perfect Cantilever System

Planning out your cantilever racking systems is about much more than just picking a size off a shelf. It’s a critical step that directly affects the safety and efficiency of your whole operation. Get the design right, and you’ll have a system that serves you for years. Get it wrong, and you could be creating serious bottlenecks and safety hazards.

This guide breaks down the essential design factors into simple, practical steps. We’ll walk you through creating a solution that’s a perfect fit for what you actually need to store. It all starts with a clear understanding of your products, then moves into the physical layout of your workspace. Nailing these details from the get-go means you invest in a system that’s effective, safe, and compliant with Australian standards.

Calculate Your Load Capacity

First things first: you absolutely must know the exact weight of the items you plan to store. Calculating the correct load capacity is non-negotiable. Overloading the arms is one of the most common—and dangerous—causes of racking failure. It’s a risk you just can’t afford to take.

Start by figuring out the weight of your heaviest bundle, pack, or single item. The arms you choose must be rated to handle this weight safely. You also need to consider the total weight that will sit on each upright column, which is simply the sum of the loads on all its arms. This total number dictates the type and strength of the column you’ll need.

Remember: The load has to be spread evenly across the arms. Placing a heavy point load right at the tip of an arm can dramatically reduce its actual capacity. If you’re ever unsure, always talk to an expert.

Determine Arm Length and Spacing

Once you know the weight, the next job is to figure out the right arm length and the spacing between your columns. The depth of your product determines the arm length—it’s that simple. The arms need to be long enough to support the full depth of your load without any major overhang, which can cause instability.

Spacing is just as vital. As a rule of thumb, the distance between the upright columns should be about half the length of the product you’re storing. For example, if you’re storing 6-metre lengths of timber, your uprights should be spaced roughly 3 metres apart. This ensures the load is always supported by at least two arms, preventing it from sagging or bowing in the middle.

Single-Sided or Double-Sided Racks?

Your choice between single-sided and double-sided units really comes down to your warehouse layout and how you want traffic to flow.

- Single-Sided Units: These have arms on only one side of the column and are designed to be placed against a wall. They’re perfect for making the most of storage space along the perimeter of your building.

- Double-Sided Units: With arms on both sides of the column, these create a central storage island with an aisle on each side. They offer much higher storage density and are ideal for open floor areas where you can set up multiple rows of racking.

Often, the most efficient setup is a mix of both. Use single-sided racks against the walls and double-sided racks to create productive aisles in the centre of your space.

Assess Your Facility Layout

Finally, you need to step back and look at the bigger picture. A perfectly designed rack is useless if it doesn’t fit your warehouse. Measure your aisle widths carefully to make sure your forklifts or other handling equipment have enough room to turn and manoeuvre safely and easily.

You also have to check your floor. A fully loaded cantilever racking system puts an incredible amount of weight onto the concrete slab below. You need to be certain your floor has the structural integrity to handle the point loads from the racking columns. Australian safety standards demand robust designs for both the racking and the environment it’s installed in. You can read more about the industrial racking systems market to get a feel for these global trends.

At Super Rack, our expert team is here to partner with you through this entire process. We offer professional guidance to design a customised, high-quality system that fits your operational needs, your budget, and your facility—all backed by fast, nationwide delivery.

Safe Installation and Ongoing Maintenance

A top-quality cantilever racking system is a fantastic asset, but its true value and safety hinge on how it’s installed and cared for. Getting the installation right from day one is non-negotiable—it protects your team and ensures your investment lasts for years. This is a job that demands precision and strict adherence to safety standards.

From there, safety becomes an ongoing commitment. Regular checks and proper use are what keep the system as solid and reliable as the day it was assembled. This focus on both setup and long-term care is what separates an effective storage solution from a potential workplace hazard.

Getting the Installation Right

The foundation of a safe cantilever rack is, quite literally, its foundation. Everything starts with a level, structurally sound concrete floor. Any unevenness or weakness in the floor can compromise the stability of the entire structure, creating a serious risk once heavy loads are applied.

With a suitable floor confirmed, the uprights must be properly anchored. This is not a step to cut corners on. Each anchor bolt must be installed according to the manufacturer’s specs and Australian Standards to ensure the columns can handle the immense forces they’ll be subjected to.

Key installation steps include:

- Floor Assessment: Ensuring the concrete is level and has the required compressive strength to support a fully loaded system.

- Correct Anchoring: Using the specified type, size, and number of anchor bolts for each base plate to secure the uprights firmly.

- Plumb and Level: Making sure every upright column is perfectly vertical (plumb) and all arms are level for even load distribution.

We always recommend professional installation to guarantee these critical steps are done right. While the specifics can differ, many of the core safety principles overlap with other systems. You can learn more in Super Rack’s guide to pallet racking installation.

Long-Term Maintenance Best Practices

Once your cantilever racking is in, a proactive maintenance schedule is your best defence against accidents. Regular inspections are crucial for catching small issues before they snowball into major safety problems. Damage from forklift impacts is one of the most common causes of racking failure, so it’s vital to have a system for spotting it early.

You should set up a regular inspection routine—weekly, monthly, or quarterly, depending on usage. This not only maintains a safe working environment but also ensures you remain compliant with regulations. To keep everything above board, it’s essential to understand the relevant Australian workplace safety standards.

What to Look For During Inspections

During your checks, make sure your team is trained to spot specific signs of wear and tear. Even minor-looking issues can point to a bigger structural problem. A simple checklist can help make these inspections consistent and thorough.

Here are the key things to check for:

- Bent or Deflected Arms: An arm that is sagging or bent has likely been overloaded or damaged. It must be replaced immediately.

- Damaged Columns: Look for any dents, scrapes, or twists in the uprights, especially near the floor where forklift impacts are common.

- Loose or Damaged Anchors: Check that all floor anchors are tight and there are no cracks in the concrete around the base plates.

- Missing Components: Ensure all safety pins, bolts, and braces are present and securely fastened.

Any damaged component, no matter how minor it seems, must be reported and dealt with straight away. A compromised part puts the entire rack’s integrity at risk. Super Rack’s expert team can provide advice on repairs and replacement parts to keep your system safe.

Promoting a Culture of Safety

Finally, remember that hardware and inspections are only half the battle. Your team’s training is just as important. Forklift operators need to be trained on safe loading and unloading techniques specific to cantilever racking, including how to distribute loads evenly and avoid bumping the structure.

Clearly displaying load capacity labels on each rack is also a legal requirement and a critical visual reminder for your staff. Make sure each arm and the total bay capacity are clearly marked. At Super Rack, our commitment to safety is reflected in our superior quality products and our expert advice, ensuring your system remains a safe, reliable asset for years to come.

Choosing the Right Supplier for Your Business

Picking the right supplier for your cantilever racking systems is a big deal. It’s more than just a purchase; it’s a major investment in your business’s safety and day-to-day efficiency. You need to find a partner you can trust, someone who delivers a long-term asset, not just a product off a shelf. Going for the cheapest option might feel good initially, but quality and expertise are what really pay off.

The starting point for any safe, long-lasting racking system is the steel it’s made from. Make sure your supplier can guarantee high-quality, certified steel. This is your peace of mind, ensuring the racks can handle their specified loads for years to come. A cheap, uncertified system might save a few dollars upfront, but it could cost you a fortune in the long run if it fails.

Look for Expertise and Customisation

Every warehouse has its own quirks, so steer clear of anyone pushing a generic, one-size-fits-all solution. A great partner will invest the time to really understand your stock, your workflow, and your floor plan. They should be able to offer expert advice to design a system that’s a perfect fit for your operation. This collaborative approach is how you get the most efficient and effective storage possible.

Don’t forget the practical stuff, either. Things like nationwide service and fast delivery are crucial. Choosing a supplier with a national footprint, like Super Rack, means you get consistent support, no matter where your business is based. Quick delivery is just as important—it keeps your project on track and minimises disruption.

When you’re weighing up suppliers, you’re looking for that perfect mix: top-tier quality, competitive pricing in Australian Dollars (AUD), genuine expert advice, and service you can actually rely on. Getting this balance right means you’re getting the best possible value for your investment.

Super Rack hits all these marks, making us a solid choice for businesses right across Australia. We’ve got everything from compact Light Duty Cantilever Racking Sets for smaller jobs to heavy-duty, completely custom builds.

Common Questions About Cantilever Racking

When you’re looking into cantilever racking systems, a few questions are bound to pop up. It’s a big investment in your business’s efficiency and safety, so getting it right is crucial. To help you out, we’ve put together some clear, straightforward answers to the queries we hear most often from business owners around Australia.

Nailing these details means you’ll end up with a system that not only fits what you need today but can also grow with you. Let’s clear up some of the key points.

Light-Duty vs Heavy-Duty Racking

One of the first decisions you’ll make is whether to go with light-duty or heavy-duty racking. The main difference is simple: load capacity.

- Light-Duty Cantilever Racking: This is your go-to for lighter materials like PVC pipes, conduit, aluminium extrusions, or small timber mouldings. It’s a great, cost-effective solution when you’re not dealing with massive weights.

- Heavy-Duty Cantilever Racking: Built for the really big stuff. This system is engineered to safely hold heavy structural steel, dense packs of hardwood, and other bulky, substantial materials. It’s made from thicker gauge steel columns, bases, and arms to handle the load.

Ultimately, your choice comes down to the weight of your products.

Can Cantilever Racks Be Used Outdoors?

Yes, absolutely—but you need the right type. Standard powder-coated racks are only designed for indoor use and will start to rust if left out in the elements. For any outdoor setup, you must use a hot-dipped galvanised finish.

This process coats the steel in a thick, protective layer of zinc, giving it fantastic protection against rain and moisture. It stops rust and corrosion in their tracks, making sure your investment stays strong and safe for years, even in the tough Australian weather.

Figuring Out Your Required Arm Capacity

Working out the arm capacity you need is absolutely critical for safety. First, figure out the maximum weight of a single bundle or item you plan to store. Then, just divide that weight by the number of arms that will be supporting it.

For example, if you have a 1,000 kg bundle of timber that will rest on two arms, each arm must have a minimum capacity of 500 kg. Always make sure your load is spread evenly across the arms. For a perfectly accurate and safe calculation, it’s always best to get an expert’s opinion.

Is Professional Installation Necessary?

We strongly recommend it. Trying to save a bit of cash with a DIY installation can create serious safety risks and might not comply with strict Australian Standards. Professional installers make sure the system is assembled correctly, anchored securely to a suitable concrete slab, and is perfectly level and plumb.

This doesn’t just guarantee the safety of your team; it also protects the long-term life of your racking. It’s also a smart move to get regular professional checks. To learn more about what’s involved, have a look at our guide on the importance of a pallet rack inspection.

For a safe, compliant, and efficient storage solution that’s perfectly matched to your business, trust the experts at Super Rack. Our team offers superior quality products, nationwide service, and the practical advice you need to get the job done right.

Contact Super Rack today for a free quote and expert consultation.