Showing 1–30 of 62 results

Super Rack is Australia’s Trusted Pallet Racking Supplier. With decades of experience and a reputation built on quality, we deliver AS4084:2023-compliant steel storage solutions, backed by 500+ reviews from satisfied customers.

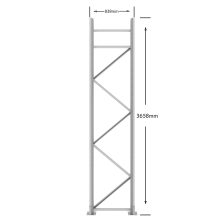

Pallet Racking is designed to hold palletised goods in horizontal rows and multiple vertical levels. By using otherwise wasted headroom, it significantly increases your facility’s capacity without expanding the building footprint.

Our warehouse storage systems are designed for maximum safety, efficiency, and space optimisation, with fast dispatch from Brisbane and Melbourne. Whether you’re expanding your warehouse or upgrading your setup, we have the right solution to keep your operations running smoothly and efficiently.

Selective Pallet Racking System is the most common type of warehouse racking, offering easy access to every pallet. This type of system usually requires lower investment and has great accessibility, but does not allow as high density as other types of system due to aisles between rows of rack.

Pallet flow rack systems are ideal for storing heaps of the same product. They use gravity rollers on a slight slope to move pallets automatically from where you load them to where you unload them. Speed controllers keep things running smoothly and safely. This storage system gives you super dense warehouse storage and guarantees a first-in, first-out (FIFO) setup. While the upfront cost is a bit higher, pallet flow racks offer big space-saving and efficiency benefits.

Push back systems are a lot like pallet flow racks, except you load and unload the pallets from the same end. This system gives you super dense storage and is designed for a last-in, first-out (LIFO) stock setup.

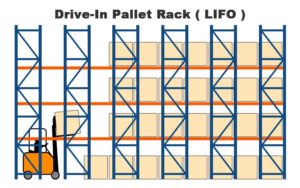

Drive-in and drive-through systems let your forklift head straight into the storage area. Pallets rest on side rails instead of the usual beams. The main difference is whether you’ve got one entry point (drive-in) or access from both sides (drive-through). Drive-in is usually for last-in, first-out (LIFO) storage, while drive-through works for first-in, first-out (FIFO). These storage systems offer super-dense warehouse storage and often cost less than pallet flow racks.

If you’re looking to boost productivity and profitability, get in touch with our team today. Our experienced industry professionals are here to help you find the perfect storage solution tailored to your needs.

4000 to 4182

4186 to 4207

4300 to 4305

3000 To 3096

3098 To 3112

3114 To 3138

3140 To 3157

3161 To 3198

3200 To 3207

Let's connect